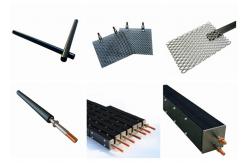

Acid Washing Rutheium Iridium Oxide Plating Basket , Anode MMO Coated

|

|

MMO Coated Titanium TA1 Anode Used For Seawater Electrolysis

The titanium anode is the anode in the titanium-based metal oxide coating. According to the different catalytic coatings on the surface, it has the function of oxygen evolution and chlorine evolution. Generally, electrode materials should have good electrical conductivity, small change in pole pitch, strong corrosion resistance, good mechanical strength and processing performance, long life, low cost, and good electrocatalytic performance for electrode reactions. At present, titanium is a metal that can meet the above comprehensive requirements, and industrial pure titanium TA1 is generally used.

The role of the metal oxide coating on the titanium anode is: low resistivity, good conductivity (the conductivity of titanium itself is not good), the chemical composition of the precious metal coating is stable, the crystal structure is stable, the electrode size is stable, and the corrosion resistance Good, long life, with good electrocatalytic performance, which is beneficial to reduce the overpotential of oxygen evolution and chlorine evolution reactions and save electric energy.

The electrolytic chlorine production technology is a safe and economical method to prevent aquatic organisms from fouling to replace the traditional environmental pollution. The electrolytic seawater chlorine production technology uses the sodium chloride contained in natural seawater to electrolyze the seawater with a precious metal-coated titanium anode to produce effective chlorine. The effective chlorine can stun or kill the spores and larvae of sea creatures and sea creatures, thereby preventing pipelines and larvae. The purpose of attaching and growing marine organisms in the cooling water system. This method is suitable for power plants, nuclear power plants, chemical plants and ships that use sea water as cooling water along the coast. Inland industrial and mining enterprises use salt to dissolve in water and dilute to about 3% to produce chlorine by electrolysis. Titanium electrodes coated with precious metals are electrolyzed to produce effective chlorine, which is added to pipelines and cooling water systems to prevent the attachment and growth of aquatic organisms. It is especially practical for industrial and mining enterprises whose cooling water system is open-type one-time cooling.

The electrolysis principle of the two methods is the same, and the following electrochemical reactions mainly occur: Anode reaction: 2Cl-Cl2↑+2e Cathodic reaction: 2H2O+2e2OH-+H2↑ Mg2++2OH-Mg(OH)2↓ The anode product reacts with the cathode product: Cl2+2OH-ClO-+Cl-+H2O Cl2+H2OHClO+H++Cl- The HClO, ClO- and Cl2 produced in the reaction are all called available chlorine.

FAQ

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Rutheium Iridium Oxide plating basket MMO Coated plating basket anode mmo Coated |

|

99% Titanium Anode |

|

Grade 2 MMO Coated Platinized Titanium Anode , Titanium Mesh Anode |

|

Iridium Tantalum 99% MMO Titanium Mesh Anode For Electrolytic Copper Foil |

|

Acid Washing 99% Mmo Coated Titanium Anodes For Copper Recovery |

|

ISO9001 Grade 1 Pure Titanium Anode , Anode Baskets For Chlor Alkali Industry |

|

Acid Washing Rutheium Iridium Oxide Plating Basket , Anode MMO Coated |