High-performance silicon nitride ceramic materials developed for the aluminum industry has significantly improved

thermal and mechanical properties than similar products. On this

basis, the "L-shaped high thermal conductivity submerged heating

"Appliance" will bring revolutionary progress to aluminum

industrial equipment.

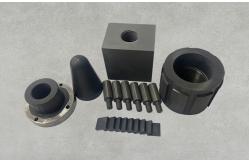

Special structural parts with high requirements for thermal shock

resistance are areas where silicon nitride ceramic materials can be

vigorously developed in the future. In application areas with high

temperature, strong corrosion, and high wear resistance, silicon

nitride ceramics are used to replace some cemented carbide,

alumina, Materials such as zirconia and silicon carbide will become

a trend.

Silicon Nitride Related Data

| Main component | 99%Al2O3 | S-SiC | ZrO2 | Si3N4 |

|

Physical

Property | Density | g/cm3 | 3.9 | 3.1 | 6 | 3.2 |

| Water Absorption | % | 0 | 0.1 | 0 | 0.1 |

| Sinter Temperature | °C | 1700 | 2200 | 1500 | 1800 |

Mechanical

Property | Rockwell Hardness | HV | 1700 | 2200 | 1300 | 1400 |

| Bend Strength | kgf/mm2 | 3500 | 4000 | 9000 | 7000 |

| Compression Intensity | Kgf/mm2 | 30000 | 20000 | 20000 | 23000 |

Thermal

Property | Maximum working

temperature | °C | 1500 | 1600 | 1300 | 1400 |

thermal expansion

coefficient

0-1000°C | /°C | 8.0*10-6 | 4.1*10-6(0-500°C) | 9.5*10-6 | 2.0*10-6(0-500°C) |

| 5.2*10-6(500-1000°C) | 4.0*10-6(500-1000°C) |

| Thermal Shock resistance | T(°C) | 200 | 250 | 300 | 400-500 |

| Thermal Conductivity | W/m.k(25°C | 31 | 100 | 3 | 25 |

| 300°C) | 16 | 100 | 3 | 25 |

Electrical

Property | Resisting rate of Volume | ◎.cm | | | | |

| 20°C | >1012 | 106-108 | >1010 | >1011 |

| 100°C | 1012-1013 | – | – | >1011 |

| 300°C | >1012 | – | – | >1011 |

Insulation Breakdown

Intensity | KV/mm | 18 | semiconductor | 9 | 17.7 |

| Dielectric Constant (1 MHz) | (E) | 10 | – | 29 | 7 |

| Dielectric Dissipation | (tg o) | 0.4*10-3 | – | – | – |