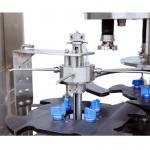

FXZ-6J Auto High-Speed in-Line Capping Machine – Universal Multi-Industry Solution

|

|

FXZ-6J In-line Capping Machine 1.Introduction 2.Machine Dimension 3.Technical Parameters

4.Electrical Configuration 5.Working Process 6.Applicable bottle type 7.Advantage 7.3 The enlarged cap sorter can store more caps. The photoelectric detection cap management system has simple adjustment, high qualification rate and strong versatility. (Optional air blowing cap management system) 7.4 The whole machine adopts Schneider's latest low energy consumption frequency converter, which is safer. Energy consumption is 20% lower than other brands. 7.5 One-time forming synchronous belt and special capping wheel, lower consumption of consumables. 7.6 Depending on the characteristics of the packaging material, a cap control mechanism and a cap opening mechanism can be optionally configured. |

|

Fertilizer 5-30L Drum Single Head Automatic Capping Machine |

|

Pesticides 5-30L Drum Single Head Automatic Capping Machine |

|

FXZ-6J Auto High-Speed in-Line Capping Machine – Universal Multi-Industry Solution |

|

1-5L Pesticide Drum Four Head Rotary Capping Machine with France Schneider Control |

|

PLC Controlled Rotary Automatic Screw Capping Machine 8 Head 50ML-1000ML Max 9000 BPH |

|

PLC Controlled Rotary Automatic Screw Capping Machine 6 Head 50ML-1000ML Max 7500 BPH |