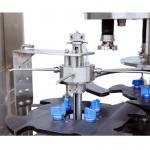

High Speed Automatic Capping Machine 100ml-1L for Agro-Inputs

|

|

Multiple Type Cap Compatible-High Speed Automatic Capping Machine 100ml-1L

Pick and place type Rotary Capping Machine is used for closing

plastics screw caps, especially for the caps with lock ring. It is

widely used in industries like foodstuff, pharmacy, daily chemical,

cosmetic, fertilizer, etc.

Technical parameters:

Bottle Inlet Part

Capping Feeding Part

3. Detection and rejection of no aluminum foil cap

4. The cap sorter

Electric Cabinet

Key Features:Cap change parts complete set to run a different size cap(option) Carbon steel base mounted on adjustable floor levelers for easy alignment Bearing frame and all surface components manufactured in 304 stainless steel Magnetic clutch capping heads for screw caps complete with pick & place cap system Caps in chute photocell, the machine will not work if there are no caps present on the chute Automatic cap feeder, chute, and applicating head Electrical socket for optional elevator feed Safety guarding with interlock devices Cap elevator to load the cap feeder automatically(option) |

|||||||||||||||||||||||||||

| Product Tags: High Speed Automatic Capping Machine 1L Automatic Capping Machine |

|

Fertilizer 5-30L Drum Single Head Automatic Capping Machine |

|

Pesticides 5-30L Drum Single Head Automatic Capping Machine |

|

FXZ-6J Auto High-Speed in-Line Capping Machine – Universal Multi-Industry Solution |

|

1-5L Pesticide Drum Four Head Rotary Capping Machine with France Schneider Control |

|

PLC Controlled Rotary Automatic Screw Capping Machine 8 Head 50ML-1000ML Max 9000 BPH |

|

PLC Controlled Rotary Automatic Screw Capping Machine 6 Head 50ML-1000ML Max 7500 BPH |