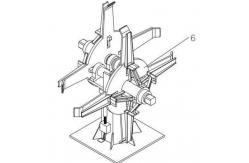

ERW Pipe Uncoiler Machine

|

|

Product Description The uncoiler can be divided into several types and three level of automation. For smaller steel coil lower than 5 tons, we normally use double arm uncoiler, and for steel coils between

5-8 tons, we usually use single arm uncoiler. For steel coil very large, we use double corn uncoilers. You also can

choose the automatic level of the uncoilers. The highest level is full automatic uncoiler, which is fully driven by

motor, the only thing you need to do is to press the button on the remote-control. The second level of automation is

pneumatic or hydraulic driven uncoilers. This type of uncoiler requires people to turn them into places but you don't

need to clamp the coils manually. They will clamp the coils by pneumatic or hydraulic driven expanders. The lowest

level of automation is mechanical uncoiler, it requires manual operation in every sections. The mechanical uncoiler is

usually used for small coils which can operate easily by hand.

Basic Technical Information: 100mm-2000mm Strip steel thickness: 1.0mm-22.0mm The maximum weight of the strip steel: 2-15 tons Automatic Double Arm Uncoiler Full automatic uncoiler, which is fully driven by motor, the only

thing you need to do is to press the button on the remote-control Pneumatic or Hydraulic Driven Uncoiler This type of uncoiler requires people to turn them into places but

you don't need to clamp the coils manually. They will clamp the coils by pneumatic or hydraulic driven expanders. Mechanical Uncoiler It requires manual operation in every sections. The mechanical

uncoiler is usually used for small coils which can operate easily by hand. Single Arm Uncoiler For steel coils between 5-8 tons, we usually use single arm

uncoiler. It usually go with a straightener of the coil ends. Double Corn Uncoilers For steel coil very large, we use double corn uncoilers. To support

a very heavy steel coil, there requires to be a supporting corn on both sides of the steel coil. And this kind

uncoiler are usually equipped with end straightener and a peeler to cut the tieing strip off. Q:Are you manufacturer? we have our own R&D department. Welcome to visit us. material (steel coil) purchase,worker training,international market

price. (2)Every shaft will be inspected for the centering jumpiness. (3)Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions. Q:Why I should choose you,what are the differences between you and other Chinese suppliers? A:We are concentrate on this industry for more than 20 years,and especially in pipe making machines. Our pipe making machine line directly export to Russia,Vietnam,lndia,Indonesia,and

many other countries in Asia, Africa, middle east and South America. |

||||||||||||||||||||||||

| Product Tags: ERW Pipe Uncoiler Machine ERW Pipe uncoiling machine | ||||||||||||||||||||||||