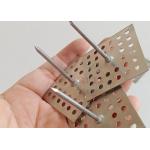

63mm Insulation Hangers With Perforated Base Fixing Insulation

Material To Wall & Ceiling

Specification details of the insulation hangers with perforated

base

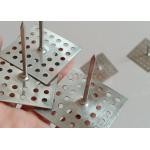

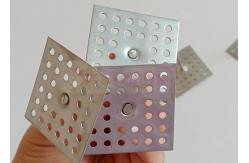

Base size in common: 40mmx40mm, 50mmx50mm

Pin diameter in common: 2mm, 2.5mm, 2.7mm, 3mm and 10ga (3.4mm)

Pin length in common: 50mm, 63mm, 90mm, 114mm, 125mm, 175mm, 203mm, 230mm

Surface treatment: zinc coated or copper coated for mild steel material

Material available |

Pin material | -mild steel: must be annealed treatment, easy for bend; zinc coated/copper plated finished for anti-rust -aluminum 1100 grade -annealed stainless steel for specification |

Base | Galvanized steel, stainless steel |

Common Size Details |

base type | pin diameter | pin length | material thickness |

25 mm x 25 mm | 1.8 mm , 2.0 mm | 20 mm - 114mm | 0.4 mm |

40 mm x 40 mm | 2.5 mm | 20 mm -180mm | 0.4 mm |

50 mm x50 mm | 2.7 mm , 3.0mm | 50 mm - 280mm | 0.4 mm |

Applications of the insulation hangers with perforated base

| 1. Wipe surface clean Perforated insulation hangers must be applied to a clean, dry,

non-painted surface. |

| 2. Apply adhesive to the bottom of the perforated insulation

hangers Spread adhesive onto the perforated base with a putty knife. |

| 3. immediately stick the insulation hangers in place. Press the hangers into position with a twisting motion to assure an

even spread of adhesive. The adhesive should protrude through the performation & beyond

the edges of base. |

| 4. Install Insulation

Note: allow adhesive to dry thoroughly before hanging insulation,

usually 24-72 hours. |

| 5. Secure with washers Secure insulation in place with a self locking washer and then bend

over or clip off the pin |

Package Details Of The Perforated Base Insulation Hangers

PIN LENGTH | CARTON SIZE | QTY/CARTON |

38MM | 41CMX28CMX17CM | 1000PCS |

50MM-65MM | 41CMX28CMX17CM | 500PCS |

70MM-84MM | 30CMX28CMX29CM | 500PCS |

90MM-120MM | 30CMX30CMX30CM | 500PCS |

130MM-160MM | 30CMX30CMX35CM | 500PCS |

170MM-203MM | 30CMX30CMX28CM | 250PCS |

OTHERS | SUPPORT CUSTOM | |

|

Why choose our HEBEI XIANGYI insulation fasteners?

1.We choose the best quality materials for making insulation

fasteners

2.We do copper plating, zinc coated and phosphating pretreatment

for the raw material using

drawing machine.

3.We purchase the multi-station cold forging machine to ensure the

better mechanical property

of shear connector to match the standard (BS EN ISO13918:2008, AWS

D1.1, etc.),

or as per customer's special requirement.

4.We use the automatic riveting machine to install .

5.After rust prevention, XIANGYI insulation fasteners can suitable

for long time ship on the sea.

6.Short delivery time because of our reasonable production flow

management