Copper Zirconium Plate C15000 For Axial Conductors Back Up Electrodes

|

|

Copper Zirconium Plate C15000 For Axial Conductors, Back-up Electrodes Product Details: Item Name: Copper Zirconium Plate C15000 Resistance Welding Manufacturing Alliance: Class1 Density at 68°F: 0.321 Lbs./In.3 Melting Point: 980℃~1080℃ Thermal Conductivity Btu/ft.2/ft./hr./°F at 68°F: 212 Principal Element: Cu, Zr Available Shape: Hexagon/Octagon Bar, Rectangle/Round/Special/Square Plate Thickness: 5mm~200mm Mechanical and Physical Testing: Elongation,Grain,Size,Hardness,Tensile,Yield

Chemical Composition: Zr: 0.15-0.20% Cu: Balance Note: Copper plus additions equal 99.90% minimum.

Fabrication Properties:

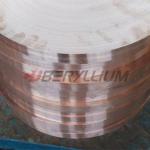

Product Photo:

Main Applications: Axial Conductors, Back-up Electrodes, Bushings, Caps & Shanks, Casting Wheels Casting Molds, Circuit Breaker Parts, Collector Connector, Collector Housing Connector Bar, Connectors, Connection Lead Bar, Continuous Casting Molds Cross Wire Welding Electrodes & Components, Damper Ring/Fingers Dies & Fixtures, Electrode Holders & Adaptors, Electrical & Mechanical Power Components End Rings & Rotor Bar, Flash & Butt Welding Dies, Flexible Connector, Joining Components

Advantages: C15000 Copper Zirconium is good replacement for C16200 Copper Cadmium. C15000 Copper Zirconium is a good replacement because of its excellent thermal and electrical conductivity while offering moderate strength. C15000 strength properties are developed through cold working (similar to C16200) whereas C18150 strength properties are developed primarily from heat treating (precipitation hardening), which is an advantage for large parts. CUBERYLLIUM®-150 Zirconium Copper is an excellent and unique copper alloy with high electrical conductivity, hardness, and ductility, moderate strength, and excellent resistance to softening at elevated temperatures. The addition of 0.15% zirconium (Zr) to copper results in a heat treatable copper alloy which may be solution treated and subsequently aged to produce these desirable properties.

Why Choose us: Cuberyllium Company is dedicated to world-class excellence. Our commitment is to continually achieve the highest standards required to meet our customer’s needs. Cuberyllium is committed to a policy of continuous improvement within all areas of the organization through customer communication, by means of quality planning and review, as well as employee training and participation to achieve the commitment goal of 100% in quality, effectiveness, and customer satisfaction. |

||||||||||||||||||||||||

| Product Tags: Copper Zirconium Plate C15000 Axial Conductors Copper Zirconium Plate |

|

SGS Zirconium Copper Alloy C15000 Round Plate For Collector Connector |

|

Copper Zirconium Plate C15000 For Axial Conductors Back Up Electrodes |

|

ASTM B224 CuZr Copper Round Rod For Resistance Welding Electrodes |

|

Copper Chromium Zirconium RWMA Class 1 C15000 Bars For Solderless Wrapped |

|

High Conductivity RWMA Class 2 Copper C18150 Rods |

|

C18150 Chromium Zirconium Copper Square Rod For Tips Rod Extensions 2 - 10mm |