EN CW106C Chromium Zirconium Copper Alloys Bars For Rod Extensions

|

|

EN CW106C Chromium Zirconium Copper Alloys Bars For Rod Extensions Chromium Zirconium Copper RWMA Class 2 Round Rods For Pencil-type Introduction: A copper chromium zirconium alloy CuCr1Zr conforming to RWMA Class 2 which is used mainly for resistance welding application but also other applications which require high electrical conductivity properties with a degree of wear resistance and a higher strength than pure copper.The alloy can also be specified to BS 2872/2874 CC102, EN 12165/12420 and Din 17673/17678-1 W Nr 2.1293.

Typical Uses: A high copper alloy with extremely good electrical and heat conductivity that is strengthened by heat treatment. Electrical The main applications are for electrical connectors,switch gear and circuit breakers which require higher mechanical properties.It is also used in generators for commutor bars and end rings for electric motors. Mechanical/Electrical Used for welding wheels,spotwelding electrodes.seam welding wheels and tips.Electrode holders and arms; oxygen jet tips. Moulds inserts for non ferrous casting moulds.

Material Properties of C18150: The C18150 copper alloy has a combination of properties as below: Tensile strength: 220-540 N/mm2 0.2% Proof strength: 100-440 N/mm2 % Elongation: 35-5 Hardness (HV): 55-175 Electrical conductivity: 80% IACS

Fabrication Properties: The most common fabrication properties of C18150 are bending, cold heading, and machining. The machinability rating of C18150 is 20. The fabrication properties of C18150 Copper can be categorized as either good, not recommended, fair, or excellent. The properties are as follows:

Available Shapes: Forms: Round bars, Flat bars, Square bars, Rectangular bars, Hexagon bars, Plates Specification: Rods/Bars/Plates/Sheets: UNS.C18150, SAE J461,463;RWMA Class 2, ISO5182-1991 European Standards: CuCr1Zr, DIN 17666 2.1293, CW106C to EN

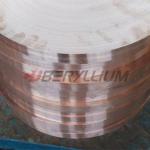

Product Photo:

CUBERYLLIUM®-815 is a high conductivity, high strength copper alloyed with chromium. C18150 is heat treatable, and resists softening in service up to temperatures of 500°C. It is used for spot and seam welding electrodes, plastic mould components and other applications requiring excellent electrical and thermal conductivity and high strength and wear resistance at high temperatures. C18150 when used for spot and seam welding electrodes can provide less sticking and resists deformation longer than copper-chromium (C18200) in some specific situations. C18150 can be used instead of C18200 in any structural or current carrying application. C18150 can be used to spot weld: cold rolled steel, hot rolled steel, nickel plated steel, zinc and zinc-aluminium coated steel (galvanised and zincalume), nickel alloys, Monel, nickel silver, stainless steel. |

||||||||||||||||

| Product Tags: EN CW106C Chromium Zirconium Copper Rod Extensions Chromium Zirconium Copper |

|

SGS Zirconium Copper Alloy C15000 Round Plate For Collector Connector |

|

Copper Zirconium Plate C15000 For Axial Conductors Back Up Electrodes |

|

ASTM B224 CuZr Copper Round Rod For Resistance Welding Electrodes |

|

Copper Chromium Zirconium RWMA Class 1 C15000 Bars For Solderless Wrapped |

|

High Conductivity RWMA Class 2 Copper C18150 Rods |

|

C18150 Chromium Zirconium Copper Square Rod For Tips Rod Extensions 2 - 10mm |