DIN 2.1293 Chromium Zirconium Copper Round Bars For Resistance Welding Electrodes

|

|

DIN 2.1293 Copper Chromium Zirconium Round Bars For Resistance Welding Electrodes Description of Copper Chromium Zirconium: Used extensively for cap style resistance welding electrodes. Evidence suggests that it can provide less sticking and resist deformation longer than its copper-chrome counterpart in some specific situations.

Physical Properties:

Equivalent Specifications: CuCr1Zr EN CW106C DIN 2.1293 ASTM C18150 RWMA Class 2

Chemical Composition:

Mechanical Properties:

Available Shapes: Forms: Round bars, Flat bars, Square bars, Rectangular bars, Hexagon bars, Plates Specification: Rods/Bars/Plates/Sheets: UNS.C18150, SAE J461,463;RWMA Class 2, ISO5182-1991 European Standards: CuCr1Zr, DIN 17666 2.1293, CW106C to EN

Applications: Electrical Industry: Resistance Welding Electrodes, Circuit Breaker Switches. Consumer: Rod Extensions, Pencil-type, Light Soldering Guns, Tips. Industrial: Welding Wheels, Tips and Rod extensions for resistance seam and spot welding.

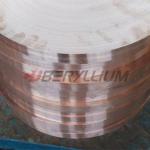

Product Photo:

CUBERYLLIUM®-815 is a high conductivity, high strength copper alloyed with chromium. C18150 is heat treatable, and resists softening in service up to temperatures of 500°C. It is used for spot and seam welding electrodes, plastic mould components and other applications requiring excellent electrical and thermal conductivity and high strength and wear resistance at high temperatures. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Round Bars Chromium Zirconium Copper DIN 2.1293 Chromium Zirconium Copper Resistance Welding Electrodes Chromium Zirconium Copper |

|

SGS Zirconium Copper Alloy C15000 Round Plate For Collector Connector |

|

Copper Zirconium Plate C15000 For Axial Conductors Back Up Electrodes |

|

ASTM B224 CuZr Copper Round Rod For Resistance Welding Electrodes |

|

Copper Chromium Zirconium RWMA Class 1 C15000 Bars For Solderless Wrapped |

|

High Conductivity RWMA Class 2 Copper C18150 Rods |

|

C18150 Chromium Zirconium Copper Square Rod For Tips Rod Extensions 2 - 10mm |