Beryllium Free Copper CuCrNi2Si C18000 Rods / Plates For Plastic Injection Mold

|

|

Beryllium Free Copper Alloys CuCrNi2Si(C18000) Rods/Plates For Plastic Injection Mold Product Normal Description:

Description of Beryllium Free Copper Alloys CuCrNi2Si(C18000)

Alloys:

About CUBERYLLIUM®: Hangzhou Cuberyllium Metal Technology Co.,Ltd. specialized in supplying beryllium copper alloys, high copper alloys, casting copper alloys, copper foil and other copper alloys. Our products have broadly been used in resistance welding, plastic injetion mold, aviation, shipbuilding, military industry, metallurgy, electronics industry and so on. We strive to offer high quality with competitive price due to our advanced technology and equipment.

Chemical Composition of Beryllium Free Copper Alloys CuCrNi2Si(C18000) Alloys: Product Grade: CUBERYLLIUM ®-180 (UNS.C18000) Cr: 0.10-0.80% Ni: 1.80-3.0% Si:0.40-0.80% Cu: Balance Note: Copper plus additions equal 99.5% minimum.

Typical Physical Properties of Beryllium Free Copper Alloys CuCrNi2Si(C18000) Alloys:

Note: 1: the units are based upon US Customary. 2: the typical physical properties apply to age hardened products.

Most Commonly Temper Used: Chromium copper rods/ bars/tubes: AT(TF00), HT(TH04) Chromiium copper plates: AT(TF00), HT(TH04)

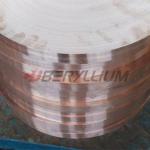

Product Photos: |

|||||||||||||||||||||||||||||||||||||||||||

| Product Tags: C18000 Beryllium Free Copper CuCrNi2Si Beryllium Free Copper Plastic Injection Mold Beryllium Free Copper |

|

SGS Zirconium Copper Alloy C15000 Round Plate For Collector Connector |

|

Copper Zirconium Plate C15000 For Axial Conductors Back Up Electrodes |

|

ASTM B224 CuZr Copper Round Rod For Resistance Welding Electrodes |

|

Copper Chromium Zirconium RWMA Class 1 C15000 Bars For Solderless Wrapped |

|

High Conductivity RWMA Class 2 Copper C18150 Rods |

|

C18150 Chromium Zirconium Copper Square Rod For Tips Rod Extensions 2 - 10mm |