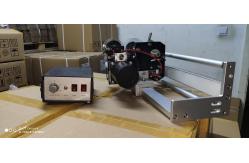

Automatic Numbering Mrp Code Printing Expiration Date Coder Hot

Stamp Coding Machine DK-700 Intermittent Ribbon Coding Machine is used to stamp various

markings onto product packaging with hot stamp ribbons. These

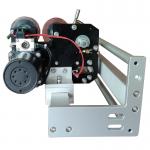

marking provide the consumer with important information, such as the expiration date, the production date, the weight, or the price. With aluminum frame & motor driving features, it can be

easily integrated on any intermittent machines without air

consumption, to provide marking in films like PP, PE, etc. This series of equipment electric ribbon code printer, printer font

clear, not easy to erase, constant temperature control, adjustable

temperature, easy to change the word, the size of the word can be

customized. Can be printed date ,batch number ,shelf life ,paper

,leather ,sticker machine and other intermittent packaging machine

matching printing , synchronous signal trigger control machine

,easy installation and operation . Using hot printing tape instead of ink for printing, adopting

special movable type loading and unloading structure, it can be

printed on any flexible packaging material. The printing is clear

and difficult to erase; Clean, no ink pollution, is an economical

and sanitary printing method. The printing of the ribbon printer is

clear and difficult to erase; Clean, free from ink pollution, it is

an economical and hygienic way to code.

Principle of ribbon coder:

The ribbon coding machine uses hot printing tape instead of ink to

print, adopts special movable type loading and unloading structure,

and can code on any flexible packaging material. Product name | DK-700 Intermittent Hot Stamp Coder | Print Area | Max 3 lines: 9mm*35mm,about 45 characters | Type Sizes | 2*3*15mm | Ribbon Size | 25mm*100m,30mm*100m,35mm*100m | Electricity | 220V/200W,single-phase | Weight | 8KG | Application | Vertical Packing Machine; Labeler | Print Speed | Max 120 PPM | Print Contents | MFG/ EXP date, lot number, serial number, etc |

|