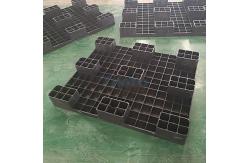

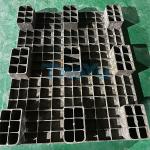

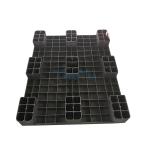

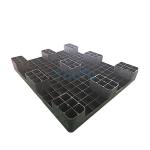

Plastic Pallet Tray Compression Molding Machine To Recycle Waste Plastics

|

|

Plastic Pallet Tray Compression Molding Machine To Recycle Waste Plastics

The plastic pallet tray compression molding machine is used to recycle waste plastics to pallets, which is differnent from injection and blowing molding machine.

While plastic recycling has become common place, one problem with increasing multifunctionality is as parts become more complex, their recycling and separation also become a more complex issue. There is therefore always going to be a tradeoff between the complexity of the product (and therefore process integration and associated energy and cost savings) and the need to provide a cradle to grave sustainable and environmentally sound solution. However, products designed with this in mind from the off-set can still be produced that achieve both. It is also necessary to consider that it is environmental legislation that drives the related search for practical and sustainable disposal solutions.

Cons of recycling are as follows:

In order to solve the problem of waste plastic pollution and recycling, after several years of research and testing, our company has explored a solution for recycling waste plastics into pallets, the product is plastic pallet tray compression molding machine, which can use most of the waste plastics for recycling, and can be made into plastics after recycling. Plastic products such as pallets have extremely low requirements for raw materials, no granulation process, and low input cost. The finished plastic products can be recycled and reused repeatedly. It is a new energy-saving and environmentally friendly recycling method for waste plastics.

What materials can be used to make pressed plastic pallets?

The plastic pallet tray compression molding machine can use waste plastics to make pressed plastic pallets, such as PE, PET, HDPE, PP, PVE, etc, which contains of carbonated drink bottles, peanut butter jars, plastic film, and microwavable packaging, etc.

plastic pallet tray compression molding machine parameters

Working principle of plastic pallet tray compression molding machine

1. Material splitting and selection (if needed) 2. Washing (if needed) 3. Shredding and crushing (if needed) 4. Drying 5. Extruding and pressing

Advantages of the plastic pallet tray compression molding machine

1. low cost, reduce 2/3 cost of the injection & blowing machine 2. No pelletizing, reduce the working process and equipment cost 3. automatic production, save labor cost 4. various materials selected, you can use most types of waste plastics to make it. 5. Environment protect |

||||||||||||||||||||

| Product Tags: Pallet Tray Compression Molding Machine Waste Plastics Compression Molding Machine Waste Plastics compression molding press | ||||||||||||||||||||

|

Automatic Plastic Pallet Making Equipment Without Pelletizing Process |

|

Plastic Pallet Tray Compression Molding Machine To Recycle Waste Plastics |

|

Compressed Plastic Pallet Injection Molding Machine For Recycle Waste Plastics |

|

Global Disposable Waste Plastic Recycling Machine To Make Plastic Pallets |

|

Waste Plastic Bottles Film Recycling Production Line For Plastic Pallets |

|

Polyethylene Terephthalate PET Waste Plastic Pallet Machine No Pelletizing |