Lab Drying Oven UV Aging Test Chamber Machine VG95218-2 58x128x135 Climatic Chamber

|

|

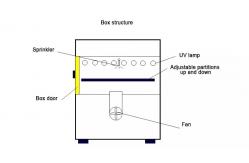

B-ZW UV Aging Test Chamber Machine VG95218-2 58x128x135 Climatic Chamber Product Description: The UV weather resistance test box uses fluorescent ultraviolet lamps and condensed water to simulate sunlight and dew conditions respectively. For example: fading, discoloration, loss of light, cracking, turbidity, blistering, embrittlement, strengthening, recession and oxidation, etc. Chamber Material: Inner container use SUS304# stainless steel plate; Outer shell use SUS304# stainless steel plate; Specimen frame use stainless steel and aluminum alloy net frame,easy access to samples; Features: TheUV accelerated aging test chamber can simulate environmental conditions such as self-climate ultraviolet rays, rain, high temperature, high humidity, dew condensation, darkness, etc. By reproducing these conditions, it is merged into a cycle, and it automatically executes the number of cycles completed. In this process, the equipment can be used for automatic monitoring of blackboard temperature and water tank temperature; by configuring irradiance measurement and control device (optional), the irradiance can be measured and controlled, and the irradiance is stable at 0.76W/m2/340nm or specified setting. Fixed value, greatly extending the service life of lamps. Mainframe Working Environment *Power requirement:220V±5%,single-phase three-wire,50Hz,8A,request 10A slow-blow fuse; *Environment:5~35℃,0~80%RH,good ventilation,Indoor environment cleaning; *Area of work about 234*353cm; *Water draining:A drain is needed on the floor near the main engine ease movement,foot wheel is installed at the bottom of the instrument,After the position is fixed, the position of the test machine is fixed with a U-ring; *For the convenience of heat dissipation and maintenance,The installation of the equipment must meet the following conditions; *Adequate maintenance space should be maintained between the equipment and walls or other equipment after installation and adjustment; Structure Profile 1.Equipment shell and inner room are selected high quality

SUS304,The most advanced processing equipment in China is used for

processing and forming; 2.The surface of the shell is sprayed with

plastic,beautiful,smooth.Color coordination,smooth line; 3.The defects of surface damage caused by aluminum plate surface

spraying are avoided.The equipment workshop is equipped with a

humidifying heater,liquid level switch,blackboard temperature

sensor etc,It also has eight ultraviolet radiation fluorescent and

UV radiometer 4.High quality immovable PU wheel is installed at the bottom of the

machine,The machine can be moved to the specified location

easily,Finally, the caster is fixed;

Light source 1.The board temperature,condensing temperature control with

controller; 2.The rest are imported electronic components: *Irradiance

uniformity:≤4%(At the surface of the sample) 3.Blackboard temperature monitoring:Use standard Pt-100 blackboard

temperature sensor,Accurate control of the sample surface

temperature during the test process; *Blackboard temperature setting range:BPT 40-75℃; *But the temperature protection inside the machine actual max

temperature is 93℃±10% *Blackboard temperature control accuracy:±0.5℃, 4.Tank temperature monitoring: *During the circle test,there's a test section is dark condensation

process,it requires high temperature saturated steam inside the

chamber,when the steam hits a relatively cold surface of the

sample,Dew will condense on the surface of the sample. *The tank is located at the bottom of the chamber,Built-in electric

heater; *Tank temperature control range:40~60℃; 5.The test chamber is equipped with a time controller,range

0~530H,backup data for power fail; 6.Safety protection equipment: *Over temperature protection in chamber:when temperature exceed

3℃±10% in chamber,the machine will automatically cut off the supply

of the lamp and heater,and go into equilibrium state cooling *Low water tank alarm,Prevent heater from burning

Our company: Packing/Shipping:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: UV Aging Test Chamber Lab Drying Oven VG95218-2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Lab Drying Oven Ozone Aging Test Chamber Lab Test Machine GB/T2951.21-2008 Environmental Chamber |

|

Lab Drying Oven UV-A Climatic Chamber Manufacturer UV Aging Test Chamber |

|

Lab Drying Oven Mathine Climatic Chamber Manufacturer VG95218-2 UV Aging Test Chamber |

|

Ozone Aging Test Chamber GB/T7762-2008 Test Machine Lab Drying Oven |

|

GJB/Z34-5.1.6 Rapid Temperature Test Chamber Lab Machine Climatic Manufacturer |

|

Lab Drying Oven UV Aging Test Chamber Machine VG95218-2 Climatic Chamber |