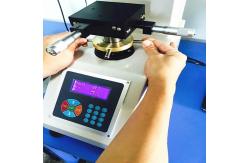

Touch Screen 88 HRA Micro Electronic Hardness Tester 8 HBW Measuring Instrument

|

|

High Quality Micro Vicker Touch Screen Digital Electronic Hardness

Tester Test the surface Rockwell hardness of steel, alloy steel, hard alloy, electroplating layer and carburizing, nit riding.

The hardness tester can be used to test the surface Rockwell hardness of steel, alloy steel, hard alloy, electroplating layer and carburizing, nit riding,

cyanide layer; It is an indispensable hardness measuring instrument in machinery, metallurgy and metrology department. 1. Brief Introduction Hardness is one of the mechanical properties of most importance in

a material’s performance, and the hardness test is an essential

measure to determine the quality of a metallic material or a part made from

the material. Hardness is the ability of a material to resist,

under certain conditions, the pressure from another solid body which will not carry any residual

deformation. The more the ability means the higher the hardness,

and vice versa. Brinell testing is mainly used in hardness determination for metallic materials such as cast iron, steel profiles, nonferrous metals and soft alloys, and also can be used for testing of hard plastics, bakelite and some other

nonmetallic materials. It is suitable for using in factories,

workshops, laboratories, universities and research institutes. 2. Product Show:

3. Product Features: l HR-150A, HR-150AI, HR-45A, XHR-150, 200HR-150 Ordinary/Surface/Plastic Rockwell hardness testers adopt mechanical manual test, without power supply, wide application range, easy operation, good economy and practicality; l The machine body is integral casting by high quality cast iron, with the automotive paint treatment process, the appearance is round and beautiful; l Read the hardness values directly from the dial, and it can be matched with other scales of Rockwell, such as: HRD, HRF etc...; l Adopt the Friction-Free spindle, high test accuracy; l Adopt the precision hydraulic buffer with integral casting, no buffer leakage; l loading is smooth, no impact, and the speed is adjustable; l The accuracy is in line with GB/T230.2-2018, ISO6508-2 and American ASTM E18 standard. 4. FAQ:

Q:What is the real delivery time of your factory?

A:10 to 15 days for general series products,meanwhile,customized products would need 20 days to 40 days based on different situations.

Q:How do you ensure the quality of your products?

A:Generally,our equipments are the most durable type in the industry,this is also the feature of the label impression of DH for most of our customers at home or abroad. However,we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q:How do you after-sale service work if the product got damaged?

A:In the guarantee time 12 months,our general aftersale serve.

|

| Product Tags: 8 HBW Electronic Hardness Tester 88 HRA Electronic Hardness Tester 88 HRA micro hardness tester |

|

Digital Micro Vickers Hardness Testing Machine |

|

HR 150A Electronic Hardness Tester |

|

Manual Portable Instrument Vickers Electronic Hardness Tester 650 HBW HRC |

|

High Precision Digital Display Micro Vickers Hardness Tester Machine Steel |

|

Touch Screen 88 HRA Micro Electronic Hardness Tester 8 HBW Measuring Instrument |

|

Portable Mini Steel Vickers Hardness Testing Machine Rockwell 220mm |