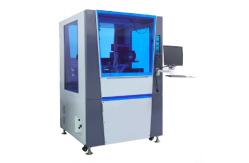

FPC Production Fully Auto Pendulum Machine Recognition And

Arrangement Fully Automatic Pendulum Machine, FPC Production Automatic Parts

Recognition And Arrangement INFINITE™ Fully Automatic Pendulum Machine is required equipment

for flexible printed circuit board production. This device is

used for part arrangement and provides part arrangement solutions

in the FPC production process, INFINITE™ Fully Automatic

Pendulum Machine is capable of FPC Automatic Parts Recognition and

Arrangement automatic identification of front and back of the

product. Automatically identify, mark, and discard NG

products. INFINITE™ Fully Automatic Pendulum Machine is

applicable for 2*2mm to 80*80mm FPC sizes. Uses a

Windows7 operation interface and is controlled through

independently developed software. INFINITE™ Fully Automatic

Pendulum Machine is capable of storing 1000 programs. Easy program

change - visual teaching repeats production change for about

5-15minutes, new product change within 30 minutes). Features: - Automatic identification of product front and back.

- The marked NG products are automatically identified and discarded.

- Independent research and development of software and hardware

- X, Y, θ alignment using linear motor +servo motor alignment high

speed, high precision: using five suction head. swing plate more

efficient.

- FPC adopts direct vibration + flat vibration feeding, which can put

a lot of materials at the same time, and can automatically vibrate

and scatter FPC; the Feeding method can be changed according to

customer requirements.

- Automatic feeding of blister board, suitable for various sizes of

the suction tray.

| TECHNICAL PARAMETERS | | Description | This device is used for part arrangement and provides part

arrangement solutions | | Operating system | Windows7 operation interface | | Control technology | Industrial computer + motion control card + automatic image

correction | | Product program storage | 1000 species | | Teaching by changing production | Visual teaching repeats production change for about 5-15minutes,

new product change within 30 minutes) | | Information display | Single-chip cycle, total output, daily output, alarm information;

other production information needs to be customized | | Precision of swing plate | ±0.15mm (excluding FPC deformation) | | Cycle Time | Up to 1 pcs/S (depending on FPC shape) | | NG plate treatment | Automatically identify the marked NG plate, and then absorb the

discarded material | | FPC material supply mode | Vibration plate or belt line automatic punch (customized according

to customer requirements) | | Supply method of blister tray | Stackable automatic feeding (0-200mm) | | Industrial camera | One 20 megapixel + one 10 megapixel | | Recognition accuracy | 0.1mm | | Main power supply | AC: 220±10%, 50/60HZ, 5KW | | Air source | 4~6 Kgf/cm2 | | SPECIFICATIONS | | Model | ABP600 | | Dimension (L*W*H MM) | L1300*W1380*H1850mm | | Shape | Floor standing | | Weight (KG) | About 1200kg | | FPC size | 2*2mm - 80*80mm | | Size of suction tray | 300*200mm - 400*350mm | | Number of suction heads | five |

|