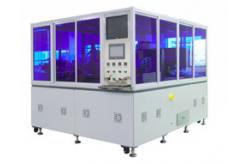

Double Sided SMT Auto Mounter EMI And CVL Laminating Machine Fully Automatic Double Sided Cover Layer Auto Mounter, EMI and CVL

laminating machine for FPC blank plate manufacturing INFINITE™ Fully Automatic Double-Sided Cover Layer Auto Mounter is a

double-sided EMI and CVL laminating machine used for FPC blank

plate manufacturing process. This INFINITE™ Series Fully

Automatic Double-Sided FPC Lamination Machine (flex PCB

overlay lamination process) has user-friendly operation

software and is easy to set up and change models. The software runs

through Windows 7 operating interface. This double-sided cover

layer automounter machine is capable of covering the front and back

EMI and CVL can be combined at the same time. Capable of

storing 1000 species and programmable by visual teaching

(repeat production change for about 5-15minutes, new product change

within 30 minutes). Features: - EMI and CVL lamination in FPC blank plate manufacturing process.

- Easy to operate and quick to change.

- The front and back EMI and CVL can be combined at the same time.

- Independent research and development of software and hardware.

- X, Y, 0 alignment using linear motor+DD motor alignment,

high-speed, high precision, using the way of heating both the upper

and lower platforms, more efficient fitting.

- The detection function is added to the tear film mechanism. When

the film is not opened, the second opening action is carried out

which greatly improves the success rate of the tear film.

- By adding the function of the turning plate, the equipment can film

both sides of FPC at the same time, reduce the transfer process of

FPC and improve the yield of FPC.

- The film cleaning function is added. The dust roller and plasma air

bar are used to remove dust, which effectively reduces the

detection rate.

- The dust removal rate of + plasma is reduced, and the dust sticking

rate is reduced.

- The throwing function of the plate and membrane is added. When the

MARK point is not recognized, the material will be thrown

automatically, which reduces the manual intervention and improves

the running smoothness of the equipment.

| TECHNICAL PARAMETERS | | Description | EMI and CVL lamination in FPC blank plate manufacturing process | | Operating system | Windows 7 operating interface | | Control technology | Industrial computer+ motion control card + image automatic

correction | | Product program storage | 1000 species | | Teaching by changing production | Visual teaching (repeat production change for about 5-15minutes,

new product change within 30 minutes) | | CVL, FPC, finished product throwing function | The function of film NG or bad material throwing can be realized, | | and when the number of throwing times exceeds the set, the alarm

will be given | | Information display | Single-chip cycle, total output, daily output, alarm information;

other production information needs to be customized | | Repeat accuracy | ±0.02mm | | Laminating precision | ±0.05 mm (excluding FPC and CVL expansion and contraction) | | Laminating cycle | Up to 5s/post at the soonest | | Joint type | 1FPC+(1-3)CVL | | Joint way | After surface A is fitted, the automatic turning board shall be

fitted to surface B | | Joint station | Double location | | Heating mode | FPC+CVL simultaneously heated | | FPC material supply mode | Stacked automatic feeding (0-50mm) | | CVL material supply mode | Stacked automatic feeding (0-50mm) | | Visual center point system | Industrial camera four Basler | | Recognition accuracy | 0.01mm | | Air source | 4-6 Kgf/cm2 | | Main power supply | AC:380±10%, 50/60H, 13KW | | SPECIFICATIONS | | Model | AF800 | | Dimension (L*W*H MM) | L2760*W2280*H1800mm | | Shape | Floor standing | | Weight (KG) | About 2500kg | | FPC size | 250*100mm - 250*420mm | | CVL size | 250*100mm - 250*500mm |

|