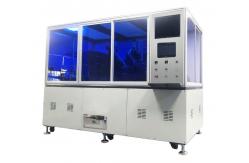

Single Sided EMI And CVL Laminating Machine For FPC Blank Plate

|

|

Single Sided EMI And CVL Laminating Machine For FPC Blank Plate

Fully Automatic Single Sided Film Mulching Machine, EMI and CVL laminating machine for FPC blank plate manufacturing

INFINITE™ Fully Automatic Single Sided Film Mulching Machine is used for EMI and CVL lamination in FPC (Flexible Printed Circuit) blank plate manufacturing process. This machine is the best option for Single-sided Printed PCB manufacturing. INFINITE™ Fully Automatic FPC Laminating Machine is easy to operate and quick to change, controlled by a Windows 7 compatible software. INFINITE™ Fully Automatic Single Sided FPC Laminating Machine has a memory of up to 1,000 programs and easy model change can be done in 20 minutes - visual teaching (repeat production change for about 5-10minutes, new product change within 20 minutes). This Single-sided PCB laminating machine is controlled through an Industrial computer + motion control card + image automatic correction.

Infinite Automation is focusing on providing innovative solutions for the factory automation process. We offer various types of factory automation solution machines, equipment, and products. You may contact our Sales Team to learn more about our product offerings.

Features:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: EMI And CVL Laminating Machine SMD Laminating Machine Laminating Machine SMD Assembly Machine | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Normal Type Conveyor INFITEK The Ultimate Solution for SMT Assembly Line Efficiency |

|

SMT AC220V Tape Cutting Machine Suitable For 0.05mm To 10mm Strips |

|

RL132 Insertion Machine Parts - N210133977AB Chuck Plate/Conveyor Clamp Repair & Replacement |

|

63W Electronic Moisture-proof Cabinet for Optimal Moisture Protection Inside Size 1198*680*1800mm |

|

Optical Performance Three Phase Isolation Transformer - Y To Y, Delta To Y, Delta To Delta |

|

FPC Production Fully Auto Pendulum Machine Recognition And Arrangement |