Rectangular 6060 6061 T6 Extruded Aluminum Alloy Bar 12m Length

|

|

Hot Selling Factory Direct Supply 6060 6061 T6 Extruded Aluminum Flat Bar with Good Price

Aluminum bars are divided into extruded aluminum bars and cast aluminum bars. Extrusion is the aluminum alloy into the extrusion cylinder and apply a certain pressure, so that it flows out of a specific die hole, so as to obtain the desired section shape and size of a processing method. Casting process editorial broadcast Casting includes melting, purification, impurity removal, gas removal, slag removal and casting process. The main process is as follows: (1) Ingredients: according to the specific grade of alloy needed to produce, calculate the addition amount of various alloy ingredients, reasonable collocation of various raw materials. (2) Smelting: the raw materials are added into the melting furnace to melt according to the process requirements, and impurities slag and gas in the melt are effectively removed by means of degassing and slag removal refining. (3) Casting: the molten aluminum is cooled and cast into round casting rods of various specifications through deep well casting system under certain casting process conditions.

Product Description

The Aluminum alloy formed by adding certain metal elements has the

advantages of keeping the pure aluminum light and high strength,

with σb values up to 24 ~ 60kgf/mm2. This makes its specific

strength better than many alloy steel and it has become an ideal

structural material to reduce the weight. Aluminum alloy

materials are widely used in machinery manufacturing, transport

machinery, power machinery and aviation industry, aircraft

fuselage, skin, compressor, etc. 1000 series aluminum alloy: belongs to the series with the most

aluminum content. The commonly used aluminum alloy includes

1050,1060 and 1100. The purity can reach more than 99.00%. Since it

does not contain other technical elements, the production process

is relatively simple and the price is relatively cheap. It is

currently the most commonly used series in conventional industries. 2000 series aluminum alloy: belong to aviation aluminum materials

with high hardness and highest copper about 3-5%. The commonly used

aluminum alloy includes 2024, 2A16, and 2A02. 3000 series aluminum alloy: belongs AL-Mn series alloy and it is

the most widely used anti-rust aluminum.Manganese is the main

component and the content is between 1.0-1.5, which makes the

aluminum alloy have good anti-rust function. The commonly used

aluminum alloy includes 3003, 3004, 3A21. 4000 series aluminum alloy: has high silicon as high as 4.5-6%. It is widely used for construction materials, mechanical parts, forging materials, welding materials due to the characteristics of heat resistance and wear resistance. The commonly used aluminum alloy is 4A01. 5000 series aluminum alloy: belongs to anti-rust aluminum, and it is called aluminum-magnesium alloy, whose magnesium content is as high as 3-5%. The main features are low density, high tensile strength and high elongation. It is also widely used in conventional industries. The commonly used aluminum alloy include 5052, 5005, 5083, and 5086. 6000 series aluminum alloy: mainly contains magnesium and silicon, thus it has the advantages of 4000 series and 5000 series. The commonly used aluminum alloy is 6061 and 6063. 6061 is a cold-treated aluminum forging product, suitable for the applications with high requirements for corrosion resistance and oxidation. It has the characteristics of easy coating and good processability. 7000 series aluminum alloy: mainly contains zinc. It also belongs to the aerospace series. It is an aluminum-magnesium-zinc-copper alloy, a heat-treatable alloy and it is a super-hard aluminum alloy with good wear resistance. The commonly used aluminum alloy is 7075. Product Display Processing technology Production Flow Chart Application Aluminum alloy bars/rods have been widely used in aviation,

aerospace, automobile, machinery manufacturing, ship building and

chemical industry. With the rapid development of science and

technology and industrial economy in recent years, the demand for

aluminum alloy welding structure is increasing. Different series of aluminum alloys have different application. 1000 series aluminum alloy application 1050: used for extruded coil tubes, various hoses, for food,

chemical and brewing industries.1060: used for chemical equipment.1100: used for chemical products, food industry installations and storage containers, Sheet work-pieces, deep-drawing or spinning concave vessels, welding parts, heat exchanger, printing plates, nameplates, reflective appliances,etc. 2000 series aluminum alloy application 2024-Due to its high strength and good fatigue strength, 2024

aluminum alloy is mainly used to make various high load parts and

components (but excluding stamping parts and forgings), such as

skeleton parts, skin, spacer frame, wing ribs, wing beams,

propeller components, rivets and other working parts below 150 ℃. 3000 series aluminum alloy application 3003- Al Mn alloy, which is the most widely used antirust aluminum.

The strength of this alloy is not high. It is used for low load

parts requiring high plasticity and good weldability, working in

liquid or gas medium, such as mailbox, gasoline or lubricating oil

conduit, various liquid containers and other low load parts made by

deep drawing: wire rod is used as rivet, and 3003 aluminum plate

has good formability, solubility and corrosion resistance. 3004 -with higher strength than 3003 alloy, mainly used in chemical

product production and storage devices, sheet processing parts,

building materials, building baffles, cable ducts, sewers, various

lamp parts, beverage cans, wave plates, building materials, color

aluminum plates and electric lamp heads. 5000 series aluminum alloy application 5005: used for conductors, cookware, instrument panels, shells and

building trim. 5052:used for marine and transportation material, railway carriage's inner and outer cabinet, oil and chemical industry storage device. 5083: used for marine applications, bodies of boats, buses, trucks

and trailer. Curtain wall panel, tanker, oil storage tank, drilling platform. 5086:used for ship board, deck, bottom and edge of panel etc. 6000 series aluminum alloy application 6061: used for trucks manufacturing, construction, ships, trams,

furniture, machinery parts, precision processing, industrial

materials,etc. 6063:used for aluminum doors and windows, curtain wall frame, in order to ensure that the doors and windows, curtain wall,etc. 6082: used for aircraft Parts, camera lenses, couplers, marine fittings and hardware, electronic fittings and joints, decorative or various hardware, hinge heads, magnetic heads, Brake Pistons, Hydraulic Pistons, electrical fittings, Valves and valve fittings,etc. 6351:used for the extrusion structure material of highway traffic facilities needs the pipeline of transporting gas, oil and water with high strength of materials, etc. 7000 series aluminum alloy application 7075 - used for manufacturing aircraft structures and high stress

structural parts and molds with high strength and strong corrosion

resistance. |

||||||||||||||||||||||||||

| Product Tags: T6 Extruded Aluminum Alloy Bar 12m 12m 6061 aluminum rectangular bar 6060 6061 aluminium alloy extruded bar |

|

Rectangular 6060 6061 T6 Extruded Aluminum Alloy Bar 12m Length |

|

10mm 15mm 20mm Aluminium Round Bar JIS DIN For Aviation Ship Industry |

|

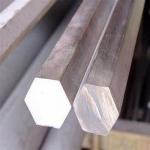

Flat Hexagon Aluminum Alloy Bar 3003 3004 3005 T3-T8 Mill Finsh |

|

ASTM AISI Round 6063 T6 Aluminum Alloy Bar For Construction |

|

Rectangular 6060 6061 T6 Extruded Aluminum Alloy Bar 12m Length |

|

10mm 15mm 20mm Aluminium Round Bar JIS DIN For Aviation Ship Industry |