Grades, Applications, Features & Corrosion Resistance.

|

|

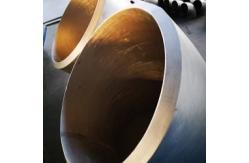

Professional Summary: Titanium Tee Fittings for Demanding Industrial Applications I specialize in supplying titanium tee fittings designed for high-performance piping systems in industries where corrosion resistance, strength, and long-term durability are critical. These fittings are essential in sectors such as chemical processing, offshore and marine engineering, aerospace systems, power generation (including nuclear and thermal plants), desalination, and environmental technology. Their primary function is to ensure reliable fluid distribution and redirection under extreme service conditions. The titanium tees I provide are manufactured in accordance with stringent international standards such as ASTM B363 and ASME B16.9, ensuring dimensional precision, metallurgical integrity, and mechanical reliability. To address a broad spectrum of operating environments, I offer tees in multiple titanium grades:

Grade 1 (GR1) and Grade 2 (GR2): Commercially pure titanium known for excellent corrosion resistance, particularly in mildly reducing and oxidizing environments such as seawater or low-concentration acid systems. These are ideal for low- to moderate-pressure applications.

Grade 5 (Ti-6Al-4V, GR5): A high-strength titanium alloy used extensively in aerospace and high-stress industrial systems. It offers superior mechanical strength and moderate corrosion resistance.

Grade 7 (GR7): Contains palladium, which significantly enhances resistance to crevice corrosion and strong oxidizing agents, including chloride-containing media.

Grade 12 (GR12): Titanium alloyed with molybdenum and nickel, offering improved weldability and excellent corrosion resistance in hot acidic environments, such as in heat exchangers and condensers.

Grade 16 (GR16): Similar to GR7, with optimized weldability and enhanced resistance to oxidizing and chlorine-rich environments, making it suitable for chlor-alkali and bleaching plants.

Each tee fitting undergoes rigorous quality assurance processes, including mechanical testing, chemical composition analysis, pressure integrity verification, and non-destructive examination (NDE) methods such as ultrasonic or dye penetrant testing. I ensure that all components meet or exceed client-specific technical and performance requirements. My commitment is to deliver engineered titanium tee solutions that not only extend the service life of piping systems but also minimize maintenance costs and improve operational safety. By combining material expertise, precise manufacturing, and industry-specific knowledge, I aim to support sustainable and efficient infrastructure across a wide range of engineering disciplines.

|

|||||||||||||||||||||||||||||||||||

| Product Tags: Chemical Titanium Pipe Fittings Marine Titanium Pipe Fittings Aerospace Titanium Pipe Fittings |

|

High-quality titanium pipe fittings made from corrosion-resistant premium materials. |

|

Grades, Applications, Features & Corrosion Resistance. |

|

Unmatched Longevity Titanium Pipe Fittings for Aggressive Processing and Power Demands |

|

Durable Titanium Eccentric and Concentric Reducers Perfect for Design-Friendly Applications |

|

ASME B16.9 30/45/60/90/180 Degree GR2 Elbows For Industrial Project |

|

90 Degree ASME B16.5 Titanium Pipe Fitting Tee Joints Pipe Forged Swagelok Elbow Fittings |