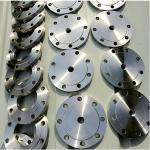

Precision-Crafted Titanium Flange Components Engineered for Extreme Performance

|

|

An Introduction to Our Titanium Flanging Capabilities At our facility, we take immense pride in our titanium flanging capabilities. Over the years, we’ve developed a specialized process that consistently delivers high-strength, precision-formed flanged parts that meet or exceed the most demanding industry standards. When it comes to flanging titanium, few can match the level of craftsmanship, consistency, and performance we offer. Titanium is a notoriously challenging material to work with due to its strength, elasticity, and sensitivity to stress and temperature. That’s exactly why flanging it properly requires not only the right equipment but also years of hands-on experience and engineering know-how. We’ve refined our flanging techniques to ensure clean edges, uniform thickness, and perfect alignment—every single time.

One of our key advantages lies in the way we control the forming process. Using custom-designed tooling, heat-assisted forming where necessary, and advanced CNC systems, we are able to produce titanium flanged parts with tight tolerances and minimal deformation. Whether it’s a simple circular flange or a complex custom contour, we guarantee dimensional accuracy and mechanical integrity. We’ve successfully manufactured titanium flanged components for a wide range of industries. In aerospace, our parts are used in engine assemblies, exhaust systems, and structural connectors due to their lightweight strength and corrosion resistance. In medical equipment, our clean, biocompatible flanges are trusted for critical implants and surgical devices. We also support marine, motorsport, and chemical processing industries, where titanium’s unique properties make it the ideal material for flanged joints and pressure vessels. What sets us apart isn’t just our technical capability—it’s our commitment to quality and collaboration. From the moment we receive a client’s specification, we engage closely with their engineering team to optimize material use, reduce waste, and ensure the finished part performs as intended under real-world conditions. Every flanged part that leaves our facility is fully inspected and traceable. In short, our titanium flanging is more than just a process—it’s a promise of precision, performance, and partnership. |

| Product Tags: Precision-Crafted Titanium Flange Components Extreme Performance Titanium Flange Components Engineered Titanium Flange Components |

|

Precision-Crafted Titanium Flange Components Engineered for Extreme Performance |

|

Flanged Parts Crafted From Strength Titanium For Enhanced Strength And Durability |

|

DN100 Class150 PN10 GR2 Titanium Flange For Different Industries And Applications |

|

Flanged Ductile Iron Pipe Hex Flange Bolts Class 150 2500 with Excellent Corrosion Resistance Forged and CNC Machined |

|

Heavy Duty Titanium Pipe Flanges ANSI/ASME/DIN Standard Welded/Threaded/Socket Weld |

|

ASME Certified Class 150 - Class 2500 Painting Surface High Pressure Pipe Flanges Cast Iron Flange |