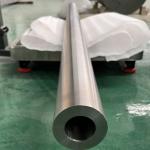

3.7165 Round Bar In Titanium Grade 5 CNC Machining Bar Material

|

3.7165 Round Bar In Titanium Grade 5 CNC Machining Bar Material

3.7165 is the material number of titanium alloy Ti-6Al-4V (also known as Grade 5 titanium alloy) in the German Industrial Standard (DIN). This alloy is one of the most widely used titanium alloys and is favored in many fields due to its excellent comprehensive properties. As a workhorse material, Grade 5 titanium bar, especially Grade 5 titanium round bars are the star product we produced and exported to our clients.

Chemical ComponentsTi-6al-4v is mainly composed of titanium (Ti), aluminum (Al) and vanadium (V), and its typical chemical composition is: titanium (Ti) residual, aluminum (Al) 5.5-6.75%, vanadium (V) 3.5-4.5%, and the limit of impurity elements such as iron (Fe), carbon (C), nitrogen (N), oxygen (O) and hydrogen (H).

Physical and Mechanical PropertiesTi-6Al-4V has high strength and good plasticity, with a density of 4.406 g/cm³ and a melting point of about 1650°C. At room temperature, the ultimate strength of the alloy is about 130 KSI (about 895 MPa, min.), the yield strength (0.2% offset) is about 120 KSI (about 828MPa, min.), and the elongation is about 10%.

Corrosion Resistance3.7165 has good corrosion resistance to seawater, Marine atmosphere and a variety of corrosive media below 300°C. This makes it widely used in Marine engineering, chemical equipment and biomedical implants.

Application FieldsTi-6Al-4V has a wide range of applications, including aerospace and aircraft structural parts, sports equipment, the medical industry (such as artificial joints and bone implants), the chemical industry, and more. Ti6Al4V Titanium alloy is mainly used in aerospace to manufacture various beams, landing gear beams, blades, shells, pressure vessels and various types of fasteners in aircraft structures, which can reduce the weight of parts by about 30%. Ti6Al4V Titanium alloys are widely used in the civil industry. For example, gas turbine blades in the electric power industry, ship thrusters in the shipbuilding industry, offshore oil drilling platforms in Marine engineering, various corrosion resistant pumps in the chemical industry, artificial implants in medicine, various sports equipment and so on. Ti6Al4V Titanium alloy can be used in the manufacture of automobile frames, crank shafts, connecting rods, bolts, oil intake valves and suspension springs.

Machining and WeldingTi Gr5/3.7165 has good thermoforming properties and is easy to weld. It is suitable to use wire made of the same grade titanium as the solder.

Ti6Al4V Titanium Round Bar Advantages

Other Ti Material We Supply:

Titanium Round BarsWe are titanium bar manufacturer, locates at Baoji City, China, which also called "Titanium Valley of China". We supply high quality titanium bars with good price and short lead time. Our main exporting areas include United states, Canada, Germany, UK, France, Turkey, South Korea, Saudi Arabia, Vietnam, etc,. Welcome to send your inquiry, thanks. Tags: Grade 5 Titanium Bar, Ti6Al4V Round Bars, Gr5 Titanium Bars |

||||||||||||||||||||||||

| Product Tags: 3.7165 Titanium Round Bar Grade 5 Titanium Round Bar CNC Machining Titanium Round Bar | ||||||||||||||||||||||||

|

High-Performance Titanium Round Bars: Grades, Uses & Key Properties |

|

High-Performance Nickel Rods Superior Corrosion Resistance |

|

Titanium Forging Rods Gr.2 ASTM B348 ASTM F67 Artificial Skeleton |

|

Gr.7 Titanium Hollow Rods ASTM B348 1.0–5.0mm Chemical Anti-corrosion |

|

Pure Titanium Rod For Medical Devices Aerospace Components And Corrosion Resistant Industrial Parts |

|

Titanium Round Bar Forgings Rolling Polished ASTM B348 ASTM F136 Annealed with 4.51 g/cm3 Density and Customizable Length |