1 - 10 of 12

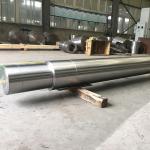

pulp dyeing printing forged shaft

Selling leads|

.... Due to the long length of the shaft, the traditional method is to use a two-part welding process. This not only reduces the reliability of the ...

2024-12-09 20:54:04

|

|

.... Due to the long length of the shaft, the traditional method is to use a two-part welding process. This not only reduces the reliability of the ...

2024-12-09 22:09:14

|

|

Nickel Alloy And Super Alloy Forged Shaft Nickel 200 C-276 for pulp and paper food processing. ADVANTAGES OF FORGED SHAFT MANUFACTURING: – Greater ...

2024-12-09 20:36:45

|

|

Nickel Alloy And Super Alloy Forged Shaft Nickel 200 C-276 for pulp and paper food processing. ADVANTAGES OF FORGED SHAFT MANUFACTURING: – Greater ...

2024-12-09 22:09:14

|

|

Duplex steel 1.4462 forged drive shaft axeltapp final machined for pulping shredder papermaking Duplex steel precision shaft is generally used as the ...

2024-12-09 20:36:45

|

|

Duplex steel 1.4462 forged drive shaft axeltapp final machined for pulping shredder papermaking Duplex steel precision shaft is generally used as the ...

2024-12-09 22:09:14

|

|

...forging parts for Pulping, printing and dyeing equipment The environment in which pulping and printing equipment is used determines that the ...

2024-12-09 20:53:20

|

|

...forging parts for Pulping, printing and dyeing equipment The environment in which pulping and printing equipment is used determines that the ...

2024-12-09 22:09:14

|

|

...ts need more complex processing technology, especially good forging performance, in order to run well in the whole equipment system. For this kind ...

2024-12-09 20:36:30

|

|

...ts need more complex processing technology, especially good forging performance, in order to run well in the whole equipment system. For this kind ...

2024-12-09 22:09:14

|