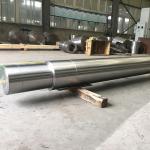

High Precision Forging Shafts 0.005mm Carbon Steel

|

|

Product Description

Custom Metal Forged High Precision Dies Hot Steel Forging Parts

Turbine machinery, such as gas turbine, steam turbine, water turbine need to use good performance, can cope with the high intensity of the environment, with good physical and chemical properties of the drive shaft

Equipment List

Detailed Images DRACHMA (ZHANGJIAGANG) MATERIAL CO.LTD has two main production plants. Zhangjiagang plant is responsible for the rough forming of workpieces, mainly forging process; While Hangzhou plant is mainly responsible for precision machining, welding and inspection of products. We implement this layout mainly to use the industrial advantages of each region to achieve maximum economic benefits.

Traditional processing enterprises often do not have such ability, the lack of blank forming ability is unable to achieve the optimal use of materials, resulting in excessive processing allowance, long cycle, high cost. Zhangjiagang is located in the southern jiangsu province, which has the strongest forging capacity in China. It has a good supporting industry and can realize the diversified production of forging and pressing blanks. Thanks to this, the product cycle of our company is faster, the cost performance is higher, and the forging products have better mechanical properties than the products directly processed by rod or plate.

In addition, our company has strong welding ability, which can weld and assemble parts to achieve system delivery. We adopt the mode of automatic robot welding and manual precision welding to achieve flexibility and high quality.

No. of employee: Production administration 15 person; Workshop 120 person; Quality and Technical 15 person.

Main Market: Europe, America, East south Asia, Korea, Japan

Management System: IS09001,TUV, PED

Sawing Machining: 6 sets

Forging Workshop: 2 tons Hammer: 3 sets,1 tons Hammer: 2 sets, Ring Rolling Machine: 2 sets Machining Workshop: CNC Machine 10 sets, CNC drilling 1 set. Common Machining 20 sets, drilling: 7 sets.

Material List we can deal

Stainless steel :304/1.4307 316/1.4404 321/1.4541 316Ti/1.4571 317L 904L F44 NO6625 UNS718 440A/B/C 431 446 F6a

Carbon Steel:A105, SA350 LF1, LF2, LF3, LF6, A707, A694, 4130, 4140, 8620, 8630, A182F5, F11, F12, F22, F91, F92

Duplex steel : F51 F60 F53 F55

Alloy Steel:4130, 4140, 4142, 4145, 4150, 4320, 4330, 4340, 4350, 4620, 4820, 6150, 8620, 8630, 8822, 9310, 52100, HY80, HY100, 9315, 300M, Nitralloy 135M, 17-22A

Aluminum : 2014, 2024, 2025, 2219, 2618, 3003, 5083, 6061, 7049, 7050, 7075, 7079, 7149, 7150, and 7175 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: High Precision Forging Shafts 0.005mm Forging Shafts DM-090 0.005mm Carbon Steel forging parts |

|

High Precision Forging Shafts 0.005mm Carbon Steel |

|

G48 A923 B TA2 TA1 Titanium Shafts For Aircraft And Aerospace Machinery |

|

AISI 6F7 AISI A2 Step Forging Shafts For Energy And Power Generation |

|

LF1 LF2 Carbon Steel Shaft A694 4130 4140 for petroleum and chemical mining |

|

Nickel Alloy Super Alloy Forging Shafts Nickel 200 C-276 For Pulp And Paper Food Processing. |

|

Duplex Steel 1.4462 1.4404 1.4410 Shaft Forging |