41 - 50 of 113

diamond tools vacuum brazing flux

Selling leads|

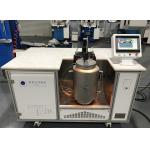

...950° and a maximum vacuum rate of 10^-2 Pa, this machine is capable of handling a wide range of materials with utmost precision and efficiency. As ...

2025-04-13 07:43:10

|

|

... brazing temperature. When brazing with active solder, the protection of active elements is a very important aspect. These elements are very easy ...

2024-12-09 18:50:49

|

|

... at high efficiency. Materials: Natural Diamond, Mono Crystal Diamond, PCD, PCBN, CVD and Cermet. Substrate Materials: Cermet, Tungsten Carbide, ...

2024-12-09 13:43:44

|

|

... Chamber Size φ180*500*4 (T)mm Max Temperature 950° Max Vacuum Rate 10-6 Torr (10-4 Pa) Brazing Vacuum Rate 10-5 Torr (10-3 Pa) Heating Source 18 ...

2024-12-09 17:13:49

|

|

...*500*4 (T)mm Max Temperature 950° Max Vacuum Rate 10-6 Torr (10-4 Pa) Brazing Vacuum Rate 10-5 Torr (10-3 Pa) Heating Source 18 pcs halogen tubes ...

2025-07-24 00:20:42

|

|

.... Secondly, the fixing flux process ensures that the material is held in place and stable during the brazing process. Thirdly, the drying process ...

2025-07-24 00:20:42

|

|

...applications, including cutting tools, wear parts, and other high-performance tools. The vacuum brazing process includes four main steps: Cleaning: ...

2025-07-24 00:20:42

|

|

... that may affect the brazing quality. The second step is fixing the flux, which is essential in removing any oxide layers on the surface of the ...

2024-12-09 20:17:45

|

|

... and durable, ensuring that it can withstand the demands of continuous operation. The brazing capability of our Vacuum Brazing Machine is ...

2024-12-09 20:17:45

|

|

... can easily monitor the brazing process as it happens, without worrying about any contamination or damage to your materials. With a maximum ...

2024-12-09 20:17:45

|