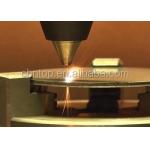

SGS Certified Cubic Boron Nitride Cutting Tools Abrasion Resistance 54mm

|

|

Solid PCBN Compact Cutting Inserts For Hard Aolly HYPERION 54mm In Stock Quick Details

Description: CBN cutter has higher wear resistance than hard alloy and ceramics, and can reduce the size deviation or size dispersion in the processing of large parts. Especially, it is suitable for the equipment with high degree of automation, which can reduce the auxiliary time of changing and adjusting the knife and make its efficiency fully play. PCBN is a blank which consists of polycrystalline CBN layer and tungsten carbide substrate. It combines the high hardness, high thermal stability of CBN and the high shock resistance of tungsten carbide. The cutting tools made from PCBN are suitable for machining high hardness ferrous metals (HRC45-68) and other alloys difficult to cut.

Our catalog for HYPERION PCBN

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: SGS cubic boron nitride cutting tools 54mm cubic boron nitride cutting tools | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Customized PCBN Blank |

|

High Wear Resistance PCBN TOOLS Customized Size PCBN Blank with Tolerance ±0.01mm |

|

Low Thermal Conductivity PCBN Blank for High Precision Machining ±0.01mm Tolerance |

|

High Oxidation Resistance Customized PCBN DISC for Customized Machining Applications |

|

Black PCBN Blank High Precision Cutting with Customized Tolerance ±0.01mm |

|

Polycrystalline Cubic Boron Nitride PCBN BLANK High Oxidation Resistance for Your Manufacturing Process |