laser direct imaging (LDI) system solutions HDI PCB

Technical advantages of LDI

(1) LDI technology adopts laser positioning and vertical laser beam

scanning, which can ensure that the graphic position deviation is

within ± 5um, which greatly improves the line alignment accuracy

and position.

(2) LDI technology does not use negative film, which can meet the

production of very high-density fine conductors, improve the

qualification rate of fine line PCB manufacturing and avoid

repeated positioning defects.

(3) LDI technology does not need to manufacture, preserve and

maintain photographic film devices, consumed materials, energy,

other auxiliary materials, and chemicals, which reduces the

production and processing cost.

(4) LDI technology can shorten the PCB manufacturing process,

reduce the turnaround time, improve the rapid response-ability,

reduce the intervention of human factors, simplify the operation

process, and then improve the production efficiency.

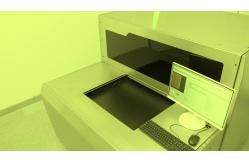

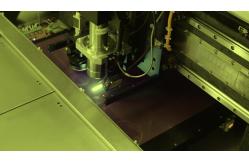

How does laser direct imaging ( LDI ) work?

Laser direct imaging needs a PCB with the photo-sensitive surface

that is positioned under a computer controlled laser. And then the

computer is creating the image on the board with the light of

laser. A computer scans the board surface into a raster image,

matching the raster image to a pre-loaded CAD or CAM design file

that includes the specifications for the necessary image intended

for the board, the laser is used for directly creating the image on

the board.

| Specification/model | DPX230 |

| Application | PCB,HDI,FPC (inner layer,outer layer,anti-welding) |

| Resolution (mass production) | 30um |

| Capacity | 30-40S@18"*24" |

| Exposure Size | 610*710mm |

| Panel thickness | 0.05mm-3.5mm |

| Alignment Mode | UV-Mark |

| Alignment capability | Outer layer±12um;Inner laye±24um |

| Line width tolerance | ±10% |

| Deviation increase and decrease mode | Fixed increase and contraction, automatic increase and contraction,

interval increase and contraction, partition alignment |

| Laser type | LD Laser,405±5nm |

| File format | Gerber 274X;ODB++ |

| Power | 380V three-phase alternating current, 6.4kW,50HZ, voltage

fluctuation range + 7% ~-10% |

| Condition | Yellow light room; Temperature 22°C ± 1°C; Humidity 50% ± 5%;

Cleanliness level 10000 and above;

Vibration requirements to avoid violent vibration near the

equipment

|

About us

We are an innovative supplier of various PCB laser direct imaging

(LDI) system solutions. Our system product portfolio ranges from

LDI system configurations for high-mix and emerging PCB niche

applications to fully automated LDI system solutions for mass

production environments.