Fast High Resolution Simultaneous Imaging Exposure For Textile

Printing

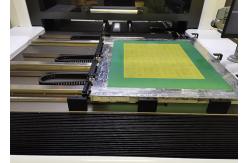

Max Screen Size 900*1000 Computer To Screen machine

CTS laser direct plate making machine is to directly read computer

data files and convert them into images, and then expose and image

them on the screen by laser projection. This kind of imaging screen

is suitable for textile printing, and also suitable for decals,

packaging, PCB, 3C Printing on glass covers, etc.

Our customer-oriented working principle strives to provide

customers with professional CTS solutions. What we buy is not only

computer to screen (CTS) equipment, but also integrated

professional solutions and services to meet customer needs.

Specification / Model | CTS100 |

| Max screen size ( mm ) | 900x1000 |

| Min screen size ( mm ) | 400x400 |

Max exposure size ( mm ) | 800x900 |

Screen frame thickness

(bespoke service is available) | 25-45mm |

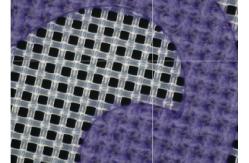

| Imaging System | DMD DLP Technology |

| Emulsion thickness (EOM) | Solvent resistant emulsion 3μm-150μm, water resistant

emulsion 3μm- 220μm |

| Exposure time | 120-240s/ ㎡, #350 yellow mesh |

| Resolution | 1270/2540dpi (Optional) |

| Raster | 133LPI |

| Focus system | Fixed focusing |

| File format | 1_bit tiff etc. |

| Laser type | UV laser, wavelength 405±5nm |

| Laser power | 20W/25W(Optional) |

| Equipment size (mm) | 1550x1330x1460 |

| Equipment net weight | 1100KG |

| Conditions | Yellow light room with cleanliness Class 10000,

temperature 22±2°C,

40-70% relative humidity (No condensation) |

| Power | Single phase 220v, 50/60HZ, 4KW(CTS200,CTS300), gas

1L/min |