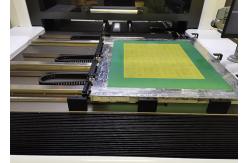

Direct Laser Image Exposure mashine For Textile Printing

Max Screen Size 900*1000 Computer To Screen machine

CTS laser direct plate making machine is to directly read computer

data files and convert them into images, and then expose and image

them on the screen by laser projection. This kind of imaging screen

is suitable for textile printing, and also suitable for decals,

packaging, PCB, 3C Printing on glass covers, etc.

CTS images are superior to traditional film positives, providing

more detail and smoother halftone transitions. Dimensional

accuracy, the error is less than one ten thousandth. All images do

not require expensive film, nor do they require the space and labor

required to store and retrieve them. Because the image information

is digitized, it is easy to store and quickly retrieve.

CTS temperature control adaptive technology, save energy costs,

reduce screen exposure time and speed up production. It only takes

3 minutes to expose each square meter of the screen, with precise

alignment and less labor.

GIS has passed ATL (TDK)/TDK qualified suppliers ISO 9001, OHSAS

18001, CE, China, the United States, Europe, South Korea, Japan,

and more than 170 patents.

Specification / Model | CTS100 |

| Max screen size ( mm ) | 900x1000 |

| Min screen size ( mm ) | 400x400 |

Max exposure size ( mm ) | 800x900 |

Screen frame thickness

(bespoke service is available) | 25-45mm |

| Imaging System | DMD DLP Technology |

| Emulsion thickness (EOM) | Solvent resistant emulsion 3μm-150μm, water resistant

emulsion 3μm- 220μm |

| Exposure time | 120-240s/ ㎡, #350 yellow mesh |

| Resolution | 1270/2540dpi (Optional) |

| Raster | 133LPI |

| Focus system | Fixed focusing |

| File format | 1_bit tiff etc. |

| Laser type | UV laser, wavelength 405±5nm |

| Laser power | 20W/25W(Optional) |

| Equipment size (mm) | 1550x1330x1460 |

| Equipment net weight | 1100KG |

| Conditions | Yellow light room with cleanliness Class 10000,

temperature 22±2°C,

40-70% relative humidity (No condensation) |

| Power | Single phase 220v, 50/60HZ, 4KW(CTS200,CTS300), gas

1L/min |