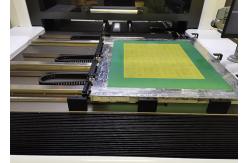

Laser Screen Direct Plate Making Computer To Screen For Screen

Printing Textile Max Screen Size 900*1000 Computer To Screen machine - CTS is a computer-to-screen (CTS) imaging and exposure system

(Chinese, Japanese, Korean, EU patent). Some rayon screens are

exposed and imaged. It is also suitable for some graphics

applications.

- Computer to screen (CTS) imaging & exposure system. CTS greatly

reduces the time and effort required to prepare images for screen

printing. The screen in the screen frame has been pictured with a

water-oil dual-use photosensitive emulsion. When it passes through

the exposure machine, the advanced DMD digital imaging technology

makes it form sharp square dots with clear definition, thereby

quickly generating opaque images. After the exposure is completed,

the stencil can be washed, and the digital image can be clearly

displayed on the screen.

- CTS images are superior to traditional film positives, providing

more detail and smoother halftone transitions. Dimensional

accuracy, the error is less than one ten thousandth. All images do

not require expensive film, nor do they require the space and labor

required to store and retrieve them. Because the image information

is digitized, it is easy to store and quickly retrieve.

The CTS exposure system simplifies the work process and improves

productivity, providing fast and excellent screen exposure with

exponentially reduced energy costs, and CTS consumes much less

energy. CTS temperature control adaptive technology, save energy

costs, reduce screen exposure time and speed up production. It only

takes 3 minutes to expose each square meter of the screen, with

precise alignment and less labor.

The combination of GIS industrial-grade 405-nanometer coupled laser

and our optical module is the only product on the market that can

reach 50% laser usage, which can greatly save customers' use costs.

Moreover, unlike expensive metal halide bulbs that need to be

replaced every two years, CTS's laser light source can be used for

10,000 hours. The CTS computer-to-screen imaging and exposure

system includes a computer, a monitor, and HQ RIP's proprietary

software.

Specification / Model | CTS100 | | Max screen size ( mm ) | 900x1000 | | Min screen size ( mm ) | 400x400 | Max exposure size ( mm ) | 800x900 | Screen frame thickness

(bespoke service is available) | 25-45mm | | Imaging System | DMD DLP Technology | | Emulsion thickness (EOM) | Solvent resistant emulsion 3μm-150μm, water resistant

emulsion 3μm- 220μm | | Exposure time | 120-240s/ ㎡, #350 yellow mesh | | Resolution | 1270/2540dpi (Optional) | | Raster | 133LPI | | Focus system | Fixed focusing | | File format | 1_bit tiff etc. | | Laser type | UV laser, wavelength 405±5nm | | Laser power | 20W/25W(Optional) | | Equipment size (mm) | 1550x1330x1460 | | Equipment net weight | 1100KG | | Conditions | Yellow light room with cleanliness Class 10000,

temperature 22±2°C,

40-70% relative humidity (No condensation) | | Power | Single phase 220v, 50/60HZ, 4KW(CTS200,CTS300), gas

1L/min |

- High Precision:

Resolutions 1270dpi or 2540dpi,

with raster 133lpi/dpi (halftones printing). 3 minutes to finish the exposure

on screen size 1000mm*1000mm. Stencil making efficieny has been

greatly improved due to a lot of time

is saved by the accurate exposure alignment

and lobor reduction. Elimination of film positives.

Litho film are becoming increasingly expensive and the number of

suppliers on the maket is rapidly decreasing. 1 procedure of

CTS digital screen making to replace 5 procedures of from the

conventional process. |