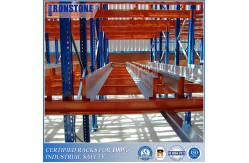

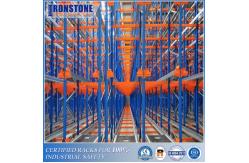

High Density Automatic Warehouse Storage Radio Shuttle Rack

|

|

High Density Automatic Warehouse Storage Radio Shuttle Rack

Radio shuttle pallet rack (radio frequency shuttle racking systems)

is an automated storage system, usually used in large-scale storage

and distribution centers. It consists of a shuttle car, some cargo

racks to support the car, and a remote control. The system

increases storage density, reduces storage costs, and increases the

speed of storage and retrieval of goods. This racking system is suitable for warehouses with a large number

of goods of the same type, and the specifications of the goods are

relatively consistent. The shuttle car can automatically carry

goods according to the predetermined route, and the remote control

can control the car. When in use, the operator places the goods on

the loading rack at the entrance, and the shuttle trolley will

automatically move the goods to the designated location in the

storage area. When picking up the goods, the shuttle trolley will

carry the goods to the exit for the operator to take out. The Radio shuttle pallet rack system can greatly improve storage

efficiency and operational efficiency, and at the same time reduce

the physical labor intensity of the operator, so it is widely used

in the modern warehousing industry.

Radio Shuttle Pallet Rack Components

Specifications of Radio Shuttle Rack

Radio shuttle pallet rack (radio frequency shuttle racking system) has the following advantages:

1. Improve storage density: Compared with traditional racking systems, Radio shuttle pallet rack can increase storage density, because it can store more goods in the same warehouse space.

2. Improve operation efficiency: The shuttle car can automatically carry goods according to the predetermined route, thereby reducing the time and labor of manual operation and improving operation efficiency.

3. Wide applicability: The radio shuttle pallet rack is suitable for large-scale storage and distribution centers, especially for warehouses with a large number of goods of the same type and relatively consistent specifications.

4. Strong flexibility: The cargo rack of the Radio shuttle pallet rack can be flexibly combined according to actual needs to accommodate goods of different specifications and volumes.

However, the Radio shuttle pallet rack also has some disadvantages:

1. High investment cost: Compared with traditional shelves, the investment cost of the Radio shuttle pallet rack is higher.

2. High maintenance cost: Since the Radio shuttle pallet rack is an automated storage system, it needs regular maintenance and maintenance, and the maintenance cost is high.

3. Professional operators have required: Radio shuttle pallet racks require professional operators to manage and maintain, and require high-quality personnel.

4. Not suitable for a wide variety of goods: The radio shuttle pallet rack is suitable for a large number of goods of the same type, not suitable for warehouses with a wide variety of goods.

The following factors need to be considered when purchasing a Radio

shuttle pallet rack (radio frequency shuttle racking system): 1. Warehouse space: When purchasing a Radio shuttle pallet rack,

factors such as the space size, height, and ground load-bearing

capacity of the warehouse need to be considered. The specifications

and models suitable for the warehouse space should be selected. 2. Types and specifications of goods: Radio shuttle pallet rack is

suitable for a large number of goods of the same type, and a

suitable loading rack and shuttle trolley should be selected

according to the type, specification and size of the goods. 3. Ways of cargo entry and exit: There are usually two ways of

entry and exit of the Radio shuttle pallet rack: one-way entry and

exit and two-way entry and exit. The appropriate entry and exit

method should be selected according to actual needs. 4. The number and height of the racks: The number and height of the

racks of the Radio shuttle pallet rack should be selected according

to the storage requirements of the warehouse and the specifications

of the goods. 5. System scalability: The scalability of the system should be

considered so that the system can be easily upgraded and expanded

when the storage capacity needs to be expanded in the future. 6. Supplier reputation and after-sales service: When purchasing

Radio shuttle pallet rack, you should choose a reputable supplier,

and consider the quality and ability of the supplier's after-sales

service. 7. Budget: When purchasing a Radio shuttle pallet rack, factors

such as budget and return on investment need to be considered, and

the appropriate model and specification should be selected

according to the actual budget and needs. Warehouse Solution Designing

Ironstone has its own design consultants who are experienced in offering you optimal storage solutions for optimizing your material and information flow. Based on engineering design, computer modeling, and CAD software design, we have successfully provided thousands of storage solutions for our customers. Through a win-win combination, we can assure you of your success in managing your goods by means of our professional technology and risk management. We can satisfy your various design requirements! |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Warehouse Storage Radio Shuttle Rack Automatic Radio Shuttle Rack Steel Q355B Radio Shuttle System | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Automatic Mobile Radio Shuttle Racking System For Save Space |

|

High Density Automatic Warehouse Storage Radio Shuttle Rack |

|

Smart Warehouse Pallet Radio Shuttle Racking System With Easily Managed |

|

Industrial Radio Shuttle Pallet Rack With Factory Price |

|

OEM Adjustable Radio Shuttle Metal Industrial Pallet Storage Warehouse Rack |

|

Semi-automated Radio Shuttle Runner Racking With Efficient Supply And Distribution |