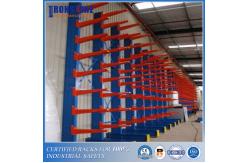

Heavy Duty Cold-Rolled Structural Steel Cantilever Storage Rack With Strong Versatility

|

|

High-Quality Warehouse Customized Cantilever Storage Pallet Metal Rack

The cantilever rack is composed of an arm mounted on the column, which can be fixed or mobile. Among them, pipe and plate storage use this type of rack more. According to the carrying capacity of the shelf, it can be divided into three types: light-weight type, medium-weight type, and weight-type. According to the structure, it can be divided into single-sided and double-sided cantilever racks.

Structure

Cantilever rack system is mostly composed made of arms, upright columns, and baseplates. Uprights are mostly made of H-structural steel or cold-rolled structural steel. Arms are made of square tube, cold rolled structural steel or H-structural steel. Plug type or bolt-connection type is used between arms and uprights, and the base and upright are connected by bolts. The cargoes are accessed by forklift or manually.

The height of the cantilever system is usually within 2.5 meters (if it is accessed by forklifts, it can be as high as 6 meters), and the length of the arm is within 1.5 meters. After adding a shelf, it is especially suitable for the warehouse with a small space and low height.

Advantages

The arms of the shelf can expand freely according to the size of the products, purchasing extra upright, arms and braces will provide an add-on unit to your existing unit, which has strong versatility.

Cantilever rack system doesn’t have a front column, which saves much of the horizontal space. Compared with other types of rack, it is more compact and selective, which can access to almost any load or storage slot.

The relatively simple structure means that the deconstruction and reconfiguration of such racks are simple. Easy installation could reduce manpower costs and improve efficiency.

|

||||||||||||||||||||||||||||||

| Product Tags: Heavy Duty Cantilever Racking System Q355 Cantilever Racking System 3000kg industrial cantilever storage racks |

|

Stable Heavy Duty Cantilever Rack For Faster Throughput And Available Work Area |

|

Warehouse Metal Anti Corrosion Cantilever Rack for Outdoor Or Indoor |

|

Galvanized Heavy Duty Cantilever Racks For Warehouse Storage With Fully Customizable |

|

Double Side Arm Heavy Duty Cantilever Warehouse Racking For Bulky Materials Storage |

|

High Load Capacity Cantilever Metal Rack With Conveniently Store |

|

Heavy Duty Cold-Rolled Structural Steel Cantilever Storage Rack With Strong Versatility |