High Density Radio Shuttle Pallet Rack System for Improved Stock Management

|

|

High Compact Radio Shuttle Pallet Racking System for Warehouse Storage

Radio Shuttle Pallet Racking System is a semi-automated storage solution based on lane storage, combining Drive-in, Pushback, and Live storage systems. The shuttle pallet is controlled remotely by the user and moved from one storage lane to another by the forklift operator. It moves goods independently by manually or automatically optimizing the lanes for storage, loading, and unloading phases.

The radio shuttle pallet racking system is ideal for storing high-density pallets of reference and bulk storage products. The use of the radio shuttle significantly reduces the maneuvering time per operation and optimizes the storage capacity of the compact system. The system uses shuttles that move independently of the racks themselves, which means that there is no need for forklifts to reach the inside of the storage aisles.

Specifications of Radio Shuttle Cart

Advantages of Radio Shuttle Pallet Racking System

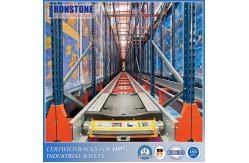

The forklift truck places the goods on top of the radio shuttle, which moves along the track and places the goods in the correct position. Several sensors precisely control the radio shuttle. The forklift operator can easily give all entry and exit commands via the remote control unit.

As there is no forklift in the lanes and due to the building's construction system, there is virtually no risk of accidents. Another advantage of the system is that there is less damage to the steel structure because the forklift trucks do not reach the racks.

Our radio shuttle systems are an efficient way of space storing bulk goods such as food, beverage, and other palletized items which are usually entered by car, pushed back, or stored in a pallet live racking system. It is particularly suitable for high volume-low SKU applications.

Our radio shuttle system converts car-free pallet racking into an automated storage solution by storing items with an automatic shuttle running on a support track.

Pallets are loaded onto the front rails from where the shuttle lifts the goods and transports it to the furthest downstream point. Built-in sensors on the shuttle racking system detect the position of the next pallet and place the new load at a predetermined, but adjustable, distance from them back to the start face. Unloading is simply the opposite operation.

Pallet shuttle movement is controlled via remote control, allowing the forklift operator to move to the next task while the shuttle moves the pallet to the correct storage location. The shuttle system is serviced by a standard forklift truck.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: LIFO Radio Shuttle Racking System Radio Shuttle Racking System 3000kg 3000kg Pallet Shuttle Racking | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Automatic Mobile Radio Shuttle Racking System For Save Space |

|

High Density Automatic Warehouse Storage Radio Shuttle Rack |

|

Smart Warehouse Pallet Radio Shuttle Racking System With Easily Managed |

|

Industrial Radio Shuttle Pallet Rack With Factory Price |

|

OEM Adjustable Radio Shuttle Metal Industrial Pallet Storage Warehouse Rack |

|

Semi-automated Radio Shuttle Runner Racking With Efficient Supply And Distribution |