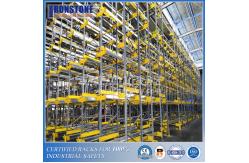

Manufacture Advanced Pallet Shuttle Metal Warehouse Storage Rack

|

|

High-Density Customizable Radio Shuttle Racking System for Warehouse Storage

Radio shuttle pallet racking system is a semi-automatic storage and retrieval solution that maintain maximum selectivity and enhance your operational efficiency at the same time. It can be easily managed with a remote control to reduce the number of aisles and make the best use of the warehouse's available space.

Forklifts are in charge of carrying pallets to the entrance of lanes in the radio shuttle pallet rack system. As for the transportation in the inner system, it is done by shuttle carts through radio and operated through remote control.

Features and Advantages of Radio Shuttle Pallet Racking System

1) Store more pallets in a lane

- Store more pallets in a given footprint

- With fewer aisles, there is less travel required resulting in more pallets moved per operator

2) Every level can be a unique SKU

- Racks have higher utilization

3) Pallets move through the rack independently of a lift truck

- Increase pallet throughput

- Reduced product damage

4) Cost-effective automation

How does the radio shuttle pallet rack work?

This semi-automated solution consists of a combination of components of conventional pallet racking and drive-in system, operated by a shuttle truck that moves the loading units within the channels. The shuttle is controlled via a remote control, is transported by a lift truck, and deposited on the level and row required.

Once the shuttle is positioned with the loading unit on it, it lifts the pallet and moves it into the channel. Using sensors and readers, the pallet is positioned in the right spot. This operation prevents the lift truck from driving into the racking, as is the case with drive-in racking systems.

The rails are supported on the racking structure and secured on the beams. The structure is dimensioned taking into account the weight of the shuttle car and the own forces caused by the movement and displacement of the loading unit within the racking.

Applications of Radio Shuttle Pallet Racking System

Applications with multiple pallets of storage for each SKU, for example:

|

||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 700mm Frame Pallet Shuttle Racking System Pallet Shuttle Racking System ODM ODM high density racking system | ||||||||||||||||||||||||||||||||||||||||||||

|

Automatic Mobile Radio Shuttle Racking System For Save Space |

|

High Density Automatic Warehouse Storage Radio Shuttle Rack |

|

Smart Warehouse Pallet Radio Shuttle Racking System With Easily Managed |

|

Industrial Radio Shuttle Pallet Rack With Factory Price |

|

OEM Adjustable Radio Shuttle Metal Industrial Pallet Storage Warehouse Rack |

|

Semi-automated Radio Shuttle Runner Racking With Efficient Supply And Distribution |