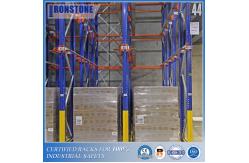

OEM Adjustable Steel Drive-in Pallet Rack For Cold Warehouse Storage

|

|

High-Density Drive in Pallet Rack System with Customizable Design

Drive-in pallet rack system is a high-density storage solution with LIFO inventory management ideal for storing a large number of like-products that are not time-sensitive. As its name implies, it allows forklifts to drive into the system directly to store and retrieve pallet cargo.

Specifically, drive-in pallet racks are placed against a wall or closed at one end, and the other end is used as entry and exit at the same time. Each lane serves as working aisles for forklifts as well as storage space for pallets. Besides, there are rails in the horizontal direction supporting pallets and guiding the direction of forklifts.

★ Loading and unloading in drive-in pallet rack system:

When it is time to load pallets, forklifts transport every pallet to the deepest available position, making pallets successively aligned from bottom to top, and from rear to front. The last pallet put into the row will be the first one to be taken out, realizing the LIFO inventory rotation direction.

★ Drive through pallet rack system:

It is a variant of the drive-in pallet rack system. Different from drive-in pallet racks, there is no barrier on both ends of drive-through pallet racks in which forklifts can drive completely through the system, making FIFO realizable. However, it’s not as stable as the drive-in pallet rack system because of the lack of connection.

Advantages of Drive in Pallet Rack System:

Tips for Drive-in Pallet Rack System:

|

||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ODM Drive In Racking System Drive In Racking System AS4084 2 Tiers AS4084 Custom Pallet Racking | ||||||||||||||||||||||||||||||||||||||||||||

|

Durable Drive In Pallet Rack With Store Homogeneous Products |

|

Convenient And Simple Warehouse FIFO High Density Drive In Pallet Racking System |

|

High Density Drive In Pallet Storage Rack System FIFO LIFO |

|

Cold Storage Warehouse Drive In Pallet Racking System |

|

CE Certificated Detachable Metal Drive In Pallet Storage Rack System |

|

CE /RMI Approved Robust Metal Drive In Storage Racking |