150MM Nickel Alloy Torispherical Dished Head Ellipsoidal Dish End Crown Radius ODM

|

|

Stainless Steel Carbon Steel Torispherical Tank Dish End Heads with Factory Price

Tank Heads Process

Pressure vessels, water tanks, gas containers and many other kinds of materials storage equipment require carefully designed tank heads and tank bodies to ensure safe storage of materials. Tank heads can be shaped in many ways by many processes. Stamping, die pressing, metal spinning and many other methods can be used to shape tank heads. Metal spinning, because it is a cold working process, can produce tank heads with excellent qualities of strength and durability as well as corrosion and chemical resistance. A cold working process is a metal working process performed at or near room temperature. Hot working processes are performed at or near a metal’s recrystallization temperature in order to make the metal easier to form. A consequence of hot working processes is the high risk of metal oxidation and a reduction in the metal’s strength. Because tank heads often are subject to intense pressure, manufacturers are more likely to choose shaping processes that are more likely to increase strength and durability. Metal spinning is one of those processes.

Specifications:

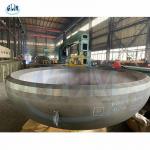

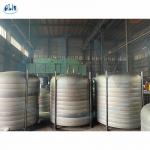

Product Display

Equipment Production

|

||||||||||||||||||||||||||

| Product Tags: 150MM Torispherical Dished Head Nickel Alloy Torispherical Dished Head ellipsoidal dish end crown radius ODM |

|

Threaded Connection Torispherical Dished End for Petroleum Processing Equipment |

|

Carbon Steel Torispherical Dished Caps And Dish Bottom And Top Crown Plates |

|

SS304 Torispherical Dish Head with Diameter of 1500mm and Thickness of 5mm |

|

DIN 28011 Torispherical Dish Heads In Carbon Steel Stainless Steel TItanium Dish Ends |

|

Q235B THB 1829 * 8 Mm Torispherical Dished Head In Philippines |

|

150MM Nickel Alloy Torispherical Dished Head Ellipsoidal Dish End Crown Radius ODM |