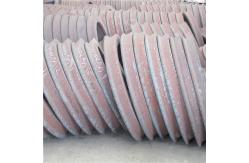

Rolled Steel Railway Tyres For Railway Vechicles CL60 R9T R8T Material

|

|

Rolled Steel Railway Tyres For Railway Vechicles CL60 R9T R8T Material Intrroduction Train wheel and tire rolling is a process of pressing and rolling

steel ingots into train wheels. Kingrail uses the components of a newly developed ultrasonic

testing instrument for testing tires.

Produce as per customer specification Big and small orders are welcome!

Welcome to contact for further details |

||||||||||||||||||

| Product Tags: CL60 Railway Tyres R9T Railway Tyres R8T Railway Tyres |

|

TB Standard Forged Train Wheel Tires For Trams And Light Rail |

|

Rolled Steel Railway Tyres For Railway Vechicles CL60 R9T R8T Material |

|

851mm Crane Rail Wheels Forging , Overhead Crane Trolley Wheels GB EN Standard |

|

Resilient Railway Tyres For Light Rail 100mm-1450mm Diameter |

|

Resilient Rail Car Wheel 550mm Tread Diameter UIC AAR Standard |

|

Kingrail Steel Rail Wheel , Locomotive Train Wheels ER6 ER7 Material |