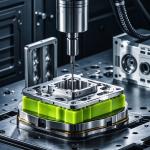

Custom Precision Cnc Injection Molding Parts Machining Plastic Abs+Pc Service

|

|

Custom Precision CNC Injection Molding Machining Plastic ABS+PC Parts Service

Quick details: 1. Keyword: CNC Machining Plastic Parts 2. Process: Injection Molding 3. Color: According To Customer Requirements 4. Place of Origin: Guangdong, China 5. Application: Medical Camera Charger Accessories 6. Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP) 7. Equipment: CNC Machining Centers 8. Lead time: 1-2 weeks

Specification:

CNC Machining Capabilities

We have a skilled engineering team with expertise in ISO9001, ISO13485, AS9000, and IATF16949 quality systems, along with ERP/MES systems, enabling us to handle one-time prototype and mass production. Our digital factory allows real-time tracking of project progress. We also utilize quality inspection equipment such as CMM and 2D measuring instruments to ensure stringent quality control.

Why Choose Us for Custom CNC Machining?

Advantages of CNC Machining

FAQ: Q1: What is the minimum size tolerance you can do? A1: The minimum size tolerance we can do is 0.001mm. Q2: What is the biggest range you can do? A2: The biggest range we can do is 1500mm. Q3: Can you do precise and complicated CNC parts? A3: Yes, we can do precise and complicated CNC parts with our 5/4/3 axis CNC machines Q4: Can you accept sample orders? A4: Yes, we can do a sample order per your requirement. |

||||||||||||||||

| Product Tags: 0.01mm tolerance injection molding parts abs+pc injection molding parts customized abs prototype injection molded parts |

|

High Durability Injection Molding Parts With Grinding / EDM / QC Processing |

|

Custom injection mold parts |

|

Customized Injection Molded Plastic Parts For Various Public Area Applications OEM |

|

Durability Public Area Injection Molded Plastic Parts For Airports And Hotels |

|

Processing plastic injection mold CNC parts |

|

Custom Precision Cnc Injection Molding Parts Machining Plastic Abs+Pc Service |