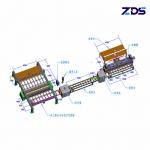

CNC Vertical Horizontal Integrated Cutting Line For Woodworking

|

|

CNC Vertical And Horizontal Integrated Cutting Line For Woodworking

Product advantages • High degree of automation, realizing unmanned operation of the cutting process • Self-contained optimization software to improve sheet utilization • Self-contained rotation function to realize complete set of cutting function • High efficiency, meeting the demand of 2000 sheets a day • Solve the problem that the board is too heavy and labor-intensive in the process of cutting the board • Solve panel quality problems caused by human factors

Main configuration of machinery • Automatic feeding device • Automatic feeding or suction cup feeding device • Automatic transfer plate device • Automatic grab/push device • Automatic Alignment Device • Automatic positioning device • Lateral Automatic Cutting Device • Automatic feeding device • Longitudinal Automatic Cutting Device Optional: • Automatic receiving device • Automatic palletizing device

Device Workflow:

Automatic feeding device: according to the production order, put the plate forklift to be processed into the lifting platform, and the lifting platform will automatically raise the plate to the set height

Automatic grab board alignment: push the board in, automatically snap, automatically grasp

Automatic cutting: The manipulator clamps automatically clamp the plate and position it forward, and automatically perform cutting

|

||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: CNC Horizontal Integrated Cutting Line CNC Vertical Integrated Cutting Line Panel Cutting Line For Woodworking |

|

PLC Automatic Computer Control Panel Production Line For Plate Cutting |

|

380V 50HZ PVC Door Panel Production Line Machine For Furniture |

|

Automatic Panel Furniture Production Line Custom CNC Router |

|

Integrated Vertical Horizontal Panel Production Line With Computer Control |

|

OEM 120m/Min Sandwich Panel Cutting Machine Computer Controlled |

|

CNC Vertical Horizontal Integrated Cutting Line For Woodworking |