Standardized Procedures for Herringbone Gears Consistent Automotive and Machine Tool Industries

|

|

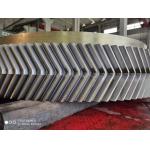

1)Description of Herringbone Gear The herringbone gear is produced by a series of precise manufacturing processes such as cutting, forging, and heat treatment, with gears featuring herringbone tooth profiles. The manufacturing accuracy of this gear has a significant impact on its transmission performance. 2)Feature of Herringbone Gear The manufacturing process is complex and requires high-precision processing equipment and specialized technology; the tooth shape processing needs to strictly control the accuracy to ensure the meshing quality of the gears; the manufacturing process involves multiple procedures, including blank manufacturing, tooth shape processing, heat treatment and surface treatment, etc. 3)Advantage of Herringbone Gear The precise manufacturing process ensures that the gears have high precision, thereby enhancing the transmission efficiency and stability; advanced manufacturing technologies enable the processing of complex structures, meeting the requirements of special working conditions; standardized manufacturing procedures guarantee the consistency of product quality. 4)Application of Herringbone Gear In the automotive industry, high-precision herringbone gears are used in automatic transmissions to enhance the smoothness of gear shifting; in the machine tool manufacturing sector, high-quality herringbone gears ensure the high precision of transmission for machine tools.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Standardized Herringbone Gears Machine Tool Herringbone Gears Automotive Herringbone Gears | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

ISO 8-9 Grade Accuracy Herringbone Gears Customizable Helix Angle For Optimal Performance |

|

Customizable Face Width Herringbone Gears for Heavy-Duty Steel Applications |

|

Herringbone Gear for Seamless Integration in Heavy Duty Applications |

|

SAE 4340 Forged Steel Pinion Herringbone Gear |

|

Standardized Procedures for Herringbone Gears Consistent Automotive and Machine Tool Industries |

|

32 Module 40CrNiMo Steel Herringbone Gears V Type Double Helical Gear |