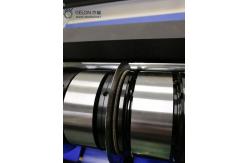

Battery Electrode Cutting Continuous Automatic Slitting Machine For

Battery Assembly Machine

1. It is used for normal lithium ion battery electrode, EV battery

electrode and super capacity electrode slitting.

2. It adopts French un-winder tension system, adjustable constant

tension un-winder with digitizing, the electrode tension is stable,

and the tension control precision is high, also with high precision

EPC system.It also could cut little undesirable electrode, so the

adaptability for electrode is good.

3. Re-winder in slip frequency shaft way, it has constant tension

or taper to adjust the tension re-winder mode, and with the

auto-tracker for neat, steady and un-wrinkle.

4. Adopts switching cutter module, aslso could be ordered several

modules with customer's request. it could achieve the battery type

transform and maintain, high efficiency.

5. PLC system

| Suitable substrate | Cathode and anode electrode of lithiumbattery |

| Suitable for substrate width | Foil Max.400mm |

| Unwinding roll | 3 in. |

| Unwinding system | Constant tension closed-loop unwindingsystem |

| Slitting system | Circular knife cutting |

| Mechanical speed | 1~50m/min |

| Reel width afte rslicing | 50-400mm |

| Slitting width precision | ±0.05mm |

| control method | PLC+Servo System |

| Scrap edge slitting width | ≥5mm |

What we supply:

1. Full set of lithium battery materials, including :

LiFePO4, LiMn2O4, LTO, LiNiMnCoO2(NMC), LiCoO2, Graphite(MCMB)and

Other Cathode&Anode Battery Materials; Aluminum foil, Copper

foils, Battery separator,etc.

2. Full set of lithium battery equipment, for example:

mixing machine --coating machine--vacuum oven--rolling

machine--welding machine--slitting / cutiing machine --winding

machine--sealed machine,etc.

3. Full set of lithium battery technology.

We can design the laboratory and production line according to

customer's request.

Any more info, pls kindly contact : mavis@libgroup.net