Double Liquid Materials Mixed Gel Packaging Machine Chemical Reaction Gel Paste Equipment Pouch

|

|

Double Liquid Materials Mixed Gel Packaging Machine Chemical Reaction Gel Paste Equipment Pouch

The mixed liquid gel patch packaging machine is an automated equipment specially used for packaging liquid, gel or semi-fluid substances. It is widely used in medicine (such as antipyretic patches, plasters), cosmetics (such as facial masks, eye patches), health products and other fields.

1. Main functions of the equipment Precision filling: It can quantitatively fill liquid or gel with high accuracy (usually within ±1% error).

Sealing molding: The patch is sealed by hot pressing, ultrasonic or cold sealing technology to prevent leakage.

Cutting and packaging: Automatically cut into the required shape (round, square, etc.) and complete single-piece packaging.

Additional functions: Some equipment supports subsequent processes such as labeling, coding, and boxing.

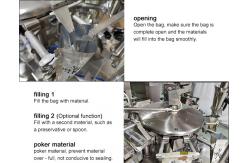

2. Core structure composition Feeding system: Store and transport liquid/gel raw materials, and may be equipped with a stirrer to prevent precipitation.

Filling head: High-precision pump (such as peristaltic pump, gear pump) controls the filling volume.

3. Molding part: Substrate unwinding: Release the backing layer (non-woven fabric, film, etc.).

Gel coating: evenly coat the liquid on the substrate.

Film sealing: cover the protective film and heat press seal.

Cutting module: mold or laser cutting to ensure neat edges.

Control system: PLC or touch screen operation, adjustable parameters (temperature, speed, filling volume, etc.).

4. Technical features Hygienic design: the contact part is made of 316 stainless steel or food-grade material, which meets GMP standards.

Wide adaptability: can handle liquids of different viscosities (such as water-based gel, silicone).

Anti-oxidation design: some equipment is equipped with nitrogen protection to prevent gel deterioration.

5. Purchase precautions Material characteristics: viscosity, corrosiveness, whether it contains particles, etc.

Capacity requirements: select semi-automatic or fully automatic models according to production.

Compliance: must comply with industry standards (such as medicines must meet FDA and CE certification).

Scalability: whether to support subsequent function upgrades (such as visual inspection).

Machine Specification:

(We can provide you with exclusive packaging machine customization services according to your needs! Of course,If you need, we can also provide you with customized bag service) |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Double Liquid Materials Mixed Gel Packaging Machine Chemical Reaction Gel Paste Equipment Pouch |

|

Eight-Station Bag-Filling Liquid Multifunctional Packaging Machine |

|

Liquid Packaging Machine Liquid Pump Rotor Pump Paste Pump Liquid Paste |

|

Gravy Soup Fruit Juice Multifunctional Packaging Machine 304/316 Stainless Steel Contact Surface Anti-oxidation / Rust |

|

Eight-Station Prefabricated Bag Liquid Packaging Machine Liquid Paste Viscous Fluidity Material Liquid Pumps |

|

Eight-station rotary liquid packaging machine prefabricated bag 304/316 stainless steel |