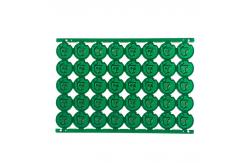

OEM PCB Manufacturing Leaded HASL / Lead free HASL Processing

|

|

Advanced PCB Manufacturing: Diverse Materials and Precise Processes

PCB Manufacturing Introduction: Experience cutting-edge PCB manufacturing with a wide range of insulation materials including FR4, aluminum, copper, ceramic, PI, and PET. Our factory specializes in 1 to 12-layer boards, offering finished plate thickness starting from 0.07mm with a tolerance of +5%/-6%. Inner layer copper thickness ranges from 18-70μm, while the outer layer boasts 20-140μm, ensuring reliable performance. Our PCBs feature various solder-resist colors and letters in red, green, yellow, blue, white, black, and silver. Explore exceptional surface treatments such as anti-oxidation, HASL, immersion gold, and more. We offer specialized processes like thick copper plating, impedance control, high-frequency plates, and single-layer copper foil gold finger plates with different sides, allowing for versatile designs. Choose from reinforcement types like Pl, FR4, steel sheet, M glue, and electromagnetic shielding film for added strength. Our PCBs can reach a maximum size of 50mm x 100mm and offer precise outer/inner line width and spacing of 0.065mm/3mil. We ensure minimum requirements for solder resist ring width, solder bridge width, solder mask window, and aperture, maintaining 10% impedance tolerance and shape precision of +0.05mm G laser +0.005mm. Forming methods like V-cut, CNC, and punching guarantee versatile fabrication options. Join us in revolutionizing electronics with these high-quality, adaptable PCB offerings.

PCB Manufacturing Parameters:

PCB Manufacturing Process: 1. Gold-plating process: the vertical HASL process is very difficult to flatten very thin pads, which brings difficulty to SMT placement. In addition, the shelf life of the HASL is very short, and gold-plating just solves the problem. these problems. 2. Immersion gold process: The purpose of the immersion gold process is to deposit a nickel-gold coating with stable color, good brightness, flat coating and good solderability on the surface of the printed circuit board. Basically, it can be divided into four stages: pre-treatment (oil extraction, micro-etching, activation, post-immersion), nickel immersion, gold immersion, and post-treatment (waste gold washing, DI washing, drying) 3. Leaded HASL: Leaded eutectic temperature is lower than lead-free, the specific amount depends on the composition of the lead-free alloy, such as the total gold of SNAGCU 217 degrees, the soldering temperature is the eutectic immersion plus 30 degrees or 50 degrees, It depends on the actual adjustment, the lead eutectic is 183 degrees, the mechanical strength, brightness, etc. are better than lead-free. 4. Lead-free HASL: lead will increase the activity of tin wire in the soldering process, lead-tin wire is better than lead-free tin wire, but lead is poisonous, long-term use is not good for human health, and lead-free tin will It is brighter than lead-tin melting, so the solder joint is much stronger. 5. SOP (anti-oxidation): It has anti-oxidation, thermal shock resistance, and corrosion resistance. It is used to protect the copper surface from rusting (oxidation or carbonization) in a normal environment: but in the subsequent welding high temperature, this protection The film must be easily removed quickly by the flux so that the exposed clean copper surface can be melted and soldered immediately in a short time to become a firm solder joint.

PCB Manufacturing Advantages: 1. From PCB proofing to SMT placement, one-stop solution, reducing R&D costs and accelerating product launch. 2. Quick quotation and quick response. 3. The delivery date is fast, and the on-time delivery rate is over 95% 4. Excellent materials, advanced equipment, and strict quality system 5. Exclusive customer service one-to-one service, seamless connection throughout the process

|

||||||||||||||||||||||||||||||||||

| Product Tags: OEM PCB Manufacturing Leaded HASL PCB Manufacturing Lead free HASL PCB Manufacturing |

|

PCB Assembly Manufacturer HASL PB Free Immersion Gold/Tin/Silver OSP Surface Finished |

|

2 - 64 Layer PCB Manufacturing Gold Finger Plating / Peelable / Carbon ink |

|

High Precision PCB Design And Manufacturing PTFE M4 M6 Materials Customizied |

|

2.4/2.4mil PCB Manufacturing 0.1mm Min Mechanical Hole One Stop Solution |

|

Nelco RCC PTFE Custom PCB Manufacturer 650mm*1130mm Max Board Size |

|

OEM PCB Manufacturing Leaded HASL / Lead free HASL Processing |