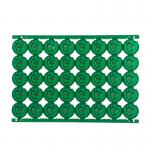

Multilayer Board PCB Manufacturing Motherboard Printed Circuit

Board PCB Manufacturing Introduce:

PCB and PCBA, as important components in the electronics industry,

play a key role in electrical interconnection and circuit support.

It is widely used in industrial control, communication modules,

medical, automotive electronics, security equipment, and other

industries. PCB printed circuit board provides the fixing and

electrical connection of electronic components, while PCBA, as the

processing process of the printed circuit board, completes the

assembly and welding of components. PCB Manufacturing Parameters: | Item | Technical Parameter | | Layer | 2-64 | | Thickness | 0.3-6.5mm | | Copper Thickness | 0.3-12 oz | | Min Mechanical Hole | 0.1mm | | Min Laser Hole | 0.075mm | | HDI | 1+n+1,2+n+2,3+n+3 | | Max Aspect Ratio | 20:01 | | Max Board Size | 650mm*1130mm | | Min Width/Space | 2.4/2.4mil | | Min Outline Tolerance | ±0.1mm | | Impedance Tolerance | ±5% | | Min PP Thickness | 0.06mm | | Bow &Twist | ≤0.5% | | Materials | FR4, High-Tg FR4, Rogers, Nelco, RCC, PTFE, M4, M6, TU862, TU872 | | Surface Finished | HASL, HASL Pb Free Immersion Gold/Tin/Silver Osp, Immersion

Gold+OSP | | Special Capability | Gold Finger Plating, Peelable, Carbon ink |

PCB Manufacturing Features:

1. One-line service from prototype to production

2. Multi-layer production: 2-68 layers

3. TPS lean production, high reliability, IATF16949, UL

certification

4. SMT capacity: 14 million advertising spaces per day |