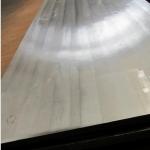

Explosion bonded Nickel Alloy N02200 + SA 516 GR70 Cladding Plate

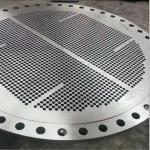

Tube Sheet for Heat Exchanger Production Explosive welding of nickel clad stainless steel plate

The method of adding a little high explosive explosive under the

detonator can reduce the detonator area and enlarge the joint area

ratio. The results of the detonation direction and the center line

of the composite board indicate that there are waveforms in the

entire joint zone. Moreover, as the detonation wave propagates, the

waveform has a development process: there is a linear combination

section at and near the detonation position, followed by a small

waveform, and then gradually increases. After 140 mm, the waveform

size and waveform shape tend to be stable. Model NO.: Nickel Alloy + Carbon steel and Stainless steel

Standard: ASTM, GB, JIS, BS

Technique: Explosion Bonded or Cold Rolled

Special Use: Corrosion Resistant Field

Name: Explosive Welded Nickel Alloy /Steel SA516 Gr70

Base Metal(mm): as Customer′s Requires

Length(mm): Request

Grade: ASTM Standard Steel

Origin: CHN

Specification: SGS, EN10204 3.1, EN10204 3.2, TUV, BV, CE | Product Name | Nickel Alloy Plate | | Length | As required | | Width | 3mm-5000mm | | Thickness | 2mm-300mm or as required | | Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. | | Technique | Explosion Bonded or Cold Rolled | | Surface Treatment | Polished, sand blast, stain brush, etching,etc. | | Material | Inconel600/601/625/718/X-750/713C,Incoloy800H/800/901/925/926/A286

Hastelloy B/B-2/C-4/C-22/C-276,

Monel400/K500,Nickel N02200/N02201 |

|