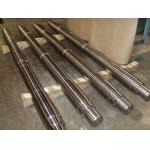

Backup Forged Steel Roller Shaft Chilled Motor Output Milling

|

Detailed Product Description

Chinese brand custom forged steel rolling mill chilled support roller shaft work backup roll pinion large shaft roll

Product Range

large parts machining complex parts machining CNC parts machining stamping parts machining

steel fabrication

About Us

The applications we serve include, but are not limited to:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: backup steel roller shaft forged steel roller shaft chilled cnc machining shaft |

Related Products

|

Lathing Large Shaft Machining 17 Meter 0.001mm Drive Shaft Micro Machining |

|

Carbon Steel Plating Spur Gear Shaft , Threaded Large Shaft |

|

Forging Large Shaft Machining Aluminum Steel Spline Gear Shaft |

|

Backup Forged Steel Roller Shaft Chilled Motor Output Milling |

|

Precision Large Shaft Machining Transmission Steel Gear Counter Shaft |

|

Steel Transmission Helical Spline Shaft Bronze Gearbox Counter |

Email to this supplier