ISO 5489-2008 Ship's Embarkation Rope Ladder

Description:

ISO5489-2008 Ship's Embarkation Rope Ladder is the equipment used

for getting on and off ships. Design & manufacture latest

Standard ISO 5489-2008 .For this essential requirement, all ships

are equipped with multiple numbers of what is known as embarkation ladders. They are nothing but foldable ladders that can hang from any

deck (especially the main or exposed deck) along the hull side and

enable the person to embark and disembark to and from the vessel.

It is also been used for crews to embark when anchoring. Light

weight, sate, used widely for various ship.

Main Technical Specification: - Technical Standard: (EU)2020/1170,item NO.MED/1.29.SOLAS 74 as

amended, Reg. III/4.III/11,III/34&X/3,LSA code,2000,HSC code 8

and IMO MSC.1/Circ 1285

- Type: Embarkation ladder, flat steps, rope seizing;

- Steps Number: 19-77, Customized;

- Length: 6000 to 25000mm, Customized;

- Material:

- Wooden part: Hardwood (e.g.: ash, oak, elm, beech, teak or apitong)

free from knots

- Side rope: Mildew-resistant manila rope or thermoset polyester rope

with a polypropylene core of a color that contrasts with the

polyester.

- Metallic materials: Metal fastener corrosion-resistant, Ferrous

metal coated, Stainless steel part at least 316, Aluminum part 5254

or 5652 alloy

- Classification Certificates: Type Approval, EC MED Type Approval

Etc.

- Making: In accordance with ISO5489:2008(E), Sec 7, the MED mark of

conformity and USCG approval number if applicable

- Application: Ship's embarkation and disembarkation

Test of ISO5489-2008 Ship's Embarkation Rope Ladder

| Test | Item to be tested | Test procedure | Acceptance criteria | Visual

examination | Fully assembled ladder. | Compare lo construction requirements In Clause 4, and the

manufacturer’s drawings. | The ladder shall comply with the construction requirements in

Clause 4, and be constructed in accordance with the manufacturer’s

drawings | | Step flexibility | Six steps, which shall include at least one of each different type,

including replacement steps, if different from steps used in the

ladders original construction. | Place each step on a pair of Supports located where the side ropes

would normally pass through the step. Apply a static load uniformly

for a period of at least 1 min over a 100mm wide contact area at

the center of the step. The load shall be 3,0 kN | Deflection at the center of the step shall not exceed 25 mm under

load There shall be no residual deflection after the load is

removed and the step is allowed to recover. | | Step fricton | One step of each different

material of construction and

step surface design One reference step constructed

of clean oak 115mn wide and 480 mm long

The step surface shall have

groove 3mm wide,3mm deep

and 15 mm apart. The grooves shall run parallel to each other and

parallel to the long edge of the step

One metal hook of a mass between 1.5 kg and 3.0 kg

The metal block shall have a flat surface no more than 100 mm wide

by 135 mm long. The flat surface shall have leather or composition

shoe-sole material attached to it. | Set the reference step in a level

position. Place the metal block

at the centre of the stepping surface of the reference step, and

with the longer edge of the metal block running across the

reference step over both edges Slowly raise one edge of the step

with the metal block on it. Measure the angle at which the block

begin to slide.

Repeat the procedure with the standard reference step and the block

under water.

Repeat the procedure in both dry and wet conditions using each

different ladder step. | The angles at which the block

begins la slide on the dry and

wet embarkation ladder step

shall be greater than or equal to

the corresponding angles measured for the standard reference step. | Step surface

durability | One step of each different

material of construction and

step surface design.

A metal block of the type described under the step friction test

arranged to enable a vertical load of 380 N to be applied to it as

it slides back and forth over the step under test | secure the Step in a horizontal position, with the loaded block

resting on it. Move the block back and forth from one end of the

step surface to the other and back In the same line, for a total of

1500 cycles.

Repeat the step friction test on the worn step in both dry and wet

conditions, making sure the sliding block is resting completely on

the worn surface

of the step | The angles at which the block

begins to slide on the dry and

wet embarkation ladder step

shall be greater than or equal to

the corresponding angle

measured for he standard

reference step. | Ladder and step

attachment

strength | Fully assembled ladder of

longest length e be approved | Suspend the ladder vertically, hanging to its full length or extend

the ladder to its full length on a horizontal surface, with the top

end of the ladder secured using its own attachments; Apply static

load of 8.8 Kn widely distributed over the bottom step for a period

of at least 1 min, So that the load is applied evenly between the

side ropes through the step attachment fittings. Repeat the

procedure at five different steps, except that the ladder is not

required to be hanging at full length and only the step under test,

its side rope attachments and the side rope immediately above the

step attachment fittings are required to be subjected to the load | Steps shall not break or crack

Attachments between any step

and a side rope shall not loosen

or break

Side ropes shall not sustain any

observable damage, elongation

or deformation that remains

after the test loads is removed | | Unrolling | Fully assembled ladder of longest length to be approved | Attach the rolled-up ladder lo anchoring fixtures in a place away

from any wall or structure that would prevent it from falling

freely, and where it can hang vertically. Allow the ladder to

unroll freely. | The steps and attachments shall

not cracked ,broken loosened.

The ladder shall not sustain damage that would make it unsafe to

use. |

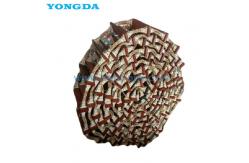

Details of ISO5489-2008 Ship's Embarkation Rope Ladder

Products of ISO5489-2008 Ship's Embarkation Rope Ladder

FAQ:

Q0: Are you a factory or trading company?

A0: We are a professional manufacturer for synthetic rope, rope

net, rope ladders and relevant etc. We also trade steel wire rope

and etc.

Q1: What is your terms of packing?

A1: We use synthetic bags for package. We can pack the goods in

your brand after your approval.

Q2: What is your terms of payment?

A2: T/T & LC.

Q3: What is your terms of delivery?

A3: EXW, FOB, CFR, CIF, DDU.

Q4: How about your delivery time?

A4: Generally, it will take 1 to 7 days after receiving payment.

The specific delivery time depends on the products and the

quantity.

Q5: Can you produce according to the samples?

A5: Yes, we can produce as your samples or drawings.

Q6: What is your sample policy?

A6: We can supply the sample it is stock available, while courier

cost and sample cost (it depends) are to be covered by buyer. It

will be refunded for next time order.

Q7: Do you test all your goods before delivery?

A7: We test our finished products & raw material by bathes, and

as requirement by third party case by case |