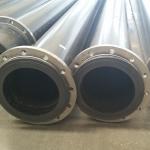

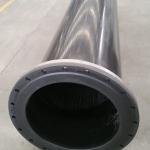

Flange Connected UHMWPE Dredging Pipe For Fluid Transportation

|

Product Description:Introduction to Ultra-high Molecular Weight Polyethylene (UHMWPE) Ultra-high molecular weight polyethylene (UHMWPE) is a type of engineering thermoplastics that boasts a viscosity-average molecular weight exceeding 2.0 million. Compared to conventional HDPE material, UHMWPE pipe exhibits superior performance in a range of applications. The Benefits of UHMWPE Pipe The unique characteristics of UHMWPE pipe make it highly desirable in many industries. Its exceptional strength and high molecular weight allow it to withstand abrasive substances and harsh conditions, such as extreme temperatures, chemical exposure, and heavy loads. Furthermore, UHMWPE is resistant to water absorption and maintains excellent mechanical properties even in sub-zero temperatures. The Advantages Over HDPE Material When compared to HDPE material, the advantages of UHMWPE pipe are clear. UHMWPE can handle higher pressure, has better abrasion resistance, and is more durable overall. Additionally, HDPE is more prone to deformation and creep, which can lead to failure over time. UHMWPE pipe's superior strength and durability, coupled with its excellent resistance to a broad range of environmental factors, make it the ideal material for use in pipelines and other critical applications. Features:Longer Life UHMWPE Pipe offers superior wear resistance compared to Q235 Steel or HDPE (PE100) pipes under the same working conditions. This means that it gives you far superior life under most operating conditions. In fact, its wear resistance is 4 to 7 times greater than that of Q235 Steel and 10 times that of HDPE (PE100) pipes. Non-Scaling The extremely smooth surface and self-lubricating properties of UHMWPE Pipe make it highly resistant to scaling. This makes it far superior to other pipeline products on the market today. Its non-stick factor is also the reason for its strength in the marine industry where it prevents the formation of barnacles. Lower Maintenance Costs, Less Maintenance Time, Less Downtime, Less Loss of Production UHMWPE Pipes offer several benefits that result in cost savings for the user. The wear resistance and weight reduction (0.93 SG) properties of UHMWPE Pipes mean that the time between pipe replacements and/or rotations can be increased while reducing installation management constraints of lifting gear and excavation requirements. This leads to lower maintenance costs, less maintenance time, less downtime, and less loss of production. Reduced Pumping Costs UHMWPE Pipes offer significant cost savings through increased pumping efficiency. With a surface roughness of 0.00022mm, UHMWPE Pipe is extremely smooth and has resultant properties superior to PTFE (Teflon). The friction coefficient of UHMWPE is 0.05, compared to 0.28 for HDPE and 0.58 for Steel (ISO 8295), which means less friction, less pressure loss, and greatly reduced energy inputs to deliver the same result. Chemical and Corrosion Resistance UHMWPE Pipe offers superior chemical resistance in acidic or corrosive applications under 85 degrees Celsius. Its chemical resistance is second only to PTFE (Teflon), which makes it the ideal choice for such applications. Lower Installation Costs The strength of UHMWPE pipes can offer savings in installation costs. The high compressive strength means reduced size or eliminating excavations (greater than 1.5x that of HDPE). The combination of strength and flexibility (>250% tensile elongation) means concrete bases are not required on wetlands and difficult terrain. The high strength and flexibility provide greater protection against damage due to ground subsidence, earthquakes, or other unexpected movement and loading of the pipeline. Furthermore, it can be laid directly on the seabed, which further reduces installation costs. Technical Parameters:

Flexible UHMWPE pipe, UHMWPE dredging pipe, Wear resistant UHMWPE pipe Applications:Support and Services:The UHMWPE pipe product technical support and services include:

|

||||||||||||||||||||

| Product Tags: Fluid Transportation UHMWPE dredging pipe Flange Connected UHMWPE dredging pipe UHMWPE dredging pipe |

|

Ultra Durable UHMWPE Pipe Unmatched Wear Corrosion Resistance for Demanding Applications |

|

Green UHMWPE Pipe With Wear Resistance And Impact Strength Diameter 1/2-48 Length 1-12m |

|

Wear Resistant Black Flecible UHMWPE Pipe S For Industrial Piping Systems |

|

Wear Resistant Steel Flange Uhmwpe Dredging Pipe Flanged Uhmwpe Pipe With Corrosion Resistance |

|

Flange Connected UHMWPE Dredging Pipe For Fluid Transportation |

|

UHMWPE Wear Resistant Pipe For Industrial Chemical Fluid Delivering |