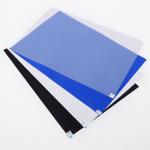

Sticky Gel SwabsSticky Gel Swabs are designed for efficient cleaning of surfaces in

highly sensitive environments such as cleanrooms. These gel

stickers provide excellent adhesion and are specifically used for

removing micro dust particles and stubborn stains from surfaces

like COB process exposed sensor coatings. Key Features- Superior Adhesion and Stickiness: The gel has excellent adhesion properties, enabling it to

effectively capture fine dust particles and contaminants on

surfaces without leaving any residue. It is especially useful for

cleaning delicate sensor surfaces where traditional cleaning

methods may cause damage or contamination.

- Non-Scratching and Non-Staining: Unlike regular cotton swabs (which use cleaning solutions to wipe

surfaces), the gel sticker won’t scratch the sensor surfaces or

leave behind any streaks or smudges. This is particularly

beneficial for improving product yield in manufacturing processes.

- Effective for Cleanroom Environments: The gel sticker is ideal for use in cleanrooms ranging from Class

10 to Class 1000 environments. It effectively removes dust

particles from LED/LCD screens, as well as debris and powder from

lens surfaces, without compromising the cleanliness of the work

area.

- Permanent Adhesion: The special gel formula ensures that the product maintains a

permanent stickiness. It does not volatilize or produce fibers,

making it more reliable than traditional cleaning methods, which

may leave fibers or residue behind.

- Gentle and Flexible: The product is soft, yet durable, making it easy to handle and

providing excellent flexibility during operation. It is non-toxic,

odorless, and environmentally friendly, ensuring that it poses no

risk to both operators and sensitive equipment.

- Electrical and Surface Protection: The gel stickers provide great protection for the electrical and

physical performance of the cleaned products. They can withstand

temperatures up to 40°C, ensuring durability under normal

operational conditions.

ApplicationsSENSOR Surface Cleaning: Removes dust and contaminants from exposed sensor surfaces during

the COB process. LED/LCD Display: Cleans fine particles from the surface of LED and LCD displays. Lens and Glass Cleaning: Removes debris and dust from lens or glass surfaces, ensuring a

clean and functional product.

|