31 - 40 of 222

precision gringding helical gears

Selling leads|

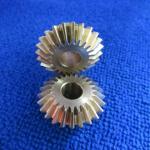

..., and the tooth shape gradually decreases from the large end to the small end. The overall shape is conical and umbrella-shaped, hence the name ...

2024-12-09 21:45:28

|

|

...gear grinding, we can achieve a high level of precision, surface finish. Gring gear Features: 1. High precision: Gear grinding enables the ...

2024-12-09 20:04:16

|

|

... and precise control of the robot's joints, making them a key component for efficient and accurate robotic operation. Advantages High precision...

2025-06-25 22:03:42

|

|

...gear has the following characteristics: Precision cutting. High density. High stiffness. Precision spiral tooth surfaces are finely matched and ...

2024-12-09 20:04:16

|

|

...output. The grinding gear, crafted through a precise grinding process, boasts higher accuracy and smoother tooth surfaces. This reduces friction, ...

2025-06-25 22:03:45

|

|

... and reduce operating vibration and noise. Helical gears have high transmission efficiency. Helical gears have a large number of gear teeth, large ...

2024-12-09 20:04:16

|

|

... change through complex gear transmission mechanisms. High-end planetary reducer generally adopts high precision helical gear, there will be ...

2024-12-09 21:45:58

|

|

.... These gears have spiral-shaped surfaces and a circular arc tooth profile, offering several key benefits. They provide smooth and quiet operation, ...

2025-06-26 07:30:10

|

|

... gear transmission. Therefore, staggered helical gear transmission is used to transmit motion and power between two staggered axes in space. The ...

2024-12-09 19:39:07

|

|

...Gear Pair Helical Tooth Meshing For Zigzag Sewing I. Design Principle —— Precision Logic of Spatial Non-Parallel Shaft Transmission This is a worm...

2025-07-17 00:25:11

|