61 - 70 of 291

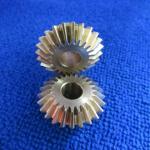

precision bevel gear

Selling leads|

... must be turned 90 degrees to drive the wheels. The helical design produces less vibration and noise than conventional straight-cut or spur-cut ...

2024-12-09 20:19:24

|

|

...gears, it is also widely used as a high-strength, low-noise gear. Product spiral hand: A right hand spiral bevel gear is one in which the outer ...

2024-12-09 20:19:24

|

|

...Bevel Gear Grinding Finished Smooth Transmission For Power Tool The driving bevel gear is used as a power input component in the mechanical ...

2025-08-01 00:19:11

|

|

...Bevel Reducer High Precision High Torque Motor Reducer With Hard Tooth Features of KF series bevel gear reduction motor: horizontal foot installati...

2024-12-09 19:39:07

|

|

... Helical-Bevel Geared Motor 90 Degree Right Angle Spiral Bevel Gear Speed Reducer Performance characteristics of K series reducer: 1. Vertical ...

2025-08-01 00:19:11

|

|

... and reduce operating vibration and noise. Helical gears have high transmission efficiency. Helical gears have a large number of gear teeth, large ...

2024-12-09 20:04:16

|

|

..., and the meshing principle is very complex. The hypoid gear counter axis has an offset distance, which makes the transmission design arrangement ...

2025-08-01 00:19:11

|

|

...Involute tooth shape: The involute tooth shape can make the gear's periodic closing smooth and impact-free, reduce noise and vibration, and improve ...

2024-12-09 20:19:24

|

|

...Bevel Gear Set For 341 Cylindrical Lockstitch Sewing Machine The role of a bevel gear in a lockstitch sewing machine, including cylindrical ...

2024-12-09 19:39:07

|

|

... in transmitting motion at an angle. Here are the key roles and functions of bevel gears in a compound feed lockstitch sewing machine: Power ...

2024-12-09 19:39:07

|